Circulating Pump Basics Explained

Scroll down to see the YouTube tutorial

Learn the basics of the typical circulation pump to understand how it works and where we use it.

Visit statesupply.com, which kindly sponsored this article. Here you can find available circulation pumps, shop for replacement parts, or talk to knowledgeable product specialists about top pump brands like Bell & Gossett and Taco. Just click here

State Supply is your source for les composants de sistèmes de chauffage à vapeur et hydroniques, tels que les purgeurs de vapeur, les vannes, les commandes et les pompes (y compris la meilleure marque de l'industrie such as Bell & Gossett, Taco, et Plus). Visit www.statesupply.com

Discover circulator pumps ➡️ https://www.statesupply.com/pump/hydronic

Watch pump repair and maintenance videos ➡️https://www.youtube.com/statesupply

Download this guide ➡️ https://www.statesupply.com/boiler-inspection-checklist

What is a circulation pump and where are they used?

Circulation pumps come in many shapes, colors, and sizes, but they generally look like these. These pumps are in-line centrifugal type pumps, which means their inlet and outlet are aligned and the method of moving the water is by centrifugal forces.

We will find these pumps used to circulate hot water through a hot water circuit so that when you turn on a tap, you have almost instant access to hot water. Otherwise, every time we turned on a faucet, we had to wait for hot water to flow through the entire system.

In hydronic heating systems we will also find these pumps used to circulate the heated water between the boiler and the radiators or other types of heat exchangers.

We can also find circulation pumps used in large heating systems to provide heat to different parts or areas of a building.

Main parts of a circulation pump.

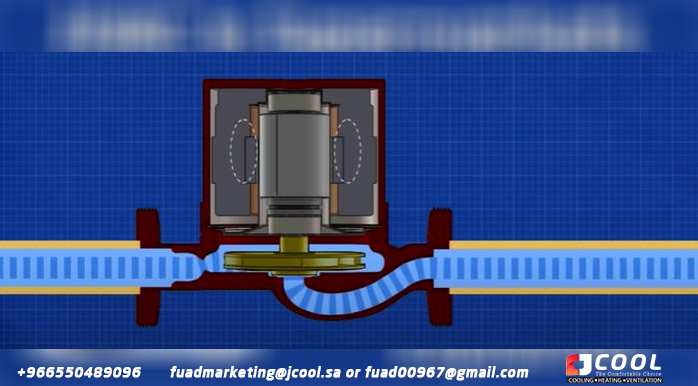

The circulation pump consists of two main parts, the pump and the motor.

The motor is an induction motor that converts electrical energy into mechanical energy. This mechanical energy is used to drive the pump and move the water.

When we look at the body of the pump, we have an input as well as an output. The pump sucks water from the inlet and pushes it towards the outlet. There will usually be an arrow on the casing to identify the flow direction so you know which is the inlet and outlet.

As this is an in-line pump the inlet and outlet are concentrically aligned, this is useful as we could potentially cut a section of pipe from a hot water system and fit a circulation pump in this space without having to modify the pipe as we do it. you would need for a standard centrifugal type pump.

It is still a centrifugal type pump, so the water must enter the pump through the eye of the impeller. To achieve this, the entrance follows this curved path that sweeps the wheel.

This part is the body of the pump. It has a channel inside known as the volute. Once the water leaves the turbine, it is collected in this channel and directed to the outlet. We will look at this in more detail later in the article.

Next we find the impeller, which sits in the pump casing and is surrounded by the volute channel. The impeller rotates and exerts a centrifugal force on the water which pushes it out of the pump and through the pipes.

Behind the wheel we have the rear license plate. The back plate acts as a barrier and maintains the flow of water into the pump casing. The back plate also contains one of the shaft bearings to ensure smooth rotation. Attached to this we will also find a rubber gasket to prevent leaks.

Next we’re going to find the shaft and rotor. The rotor is attached to the shaft and the shaft is attached to the impeller. When the rotor rotates so will the shaft and impeller. That’s the driving force of the water within the pump.

The rotor is located in the rotor case. The rotor can provide a physical barrier that prevents water from coming into contact with the electrical circuitry of the induction motor.

Around the rotor we can have the induction motor. It consists of a series of coils of copper wire that are closely packed inside the stator. The coils and the stator are fixed and do not rotate. Electricity flows through the coils inside the stator, this will create a rotating electromagnetic field that will spin the rotor.

P

Inside the terminal box we have the gear selector. We also have ground, neutral and line terminals that allow us to connect the pump to our power source. There is usually a capacitor inside this type of pump as well, the capacitor is vital to the operation of the pump so we will look at that in detail shortly.

Motor windings and capacitor

The electric motor of the circulation pump is a single phase AC induction motor.

Electricity is the flow of electrons through a wire. We have direct or direct current that we get from supplies like batteries, and in this type of electricity, the electrons flow in only one direction from negative to positive.

But the power sources in their homes and workplaces will be from a different type of electricity known as alternating current. With alternating current, electrons alternate in direction and flow back and forth repeatedly.

When electricity flows through a wire, it creates an electromagnetic field. As the electrons change direction, the magnetic field continually expands and contracts. By winding the wire into a coil, we generate a much stronger electromagnetic field.

When a wire is wound in a coil, we call it inductance. When we apply an alternating current the magnetic field expands and collapses, each time it expands and collapses the north and south polarity of the coil is reversed. We need this expanding and collapsing magnetic field to create rotation.

To form the motor, we wrap the wire around two coils inside the stator to create a large electromagnetic field. If we place a rotor in the center of this magnetic field, the rotor will align itself with the magnetic field and then stop. To make the rotor spin, we need a rotating magnetic field. If we were to take magnets and carefully time them to interact with the rotor, we could achieve this, but it's not very practical.

In larger motors, we create the rotating magnetic field using more phases because the electrons flow back and forth at a different time in the two phases, so this will create another magnetic field at a different time. However, this type of pump only has a single phase connection, so we will use a capacitor instead to create a dummy 2nd phase.

Therefore, we insert a second coil into the stator at 90 degrees of rotation from the first coil. The two coils are connected in parallel, but the second coil has a capacitor connected in series with the coil.

Electricity does not pass through capacitors. The circuit is cut inside a capacitor to form two walls. The two inner walls are very close to each other, so electrons can accumulate on these walls and also be released from here. Therefore, the capacitor resembles a storage tank or a diaphragm. When the electricity supply moves in one direction, the capacitor stores electrons. When the power supply changes direction, the capacitor releases electrons

This way we have electrons flowing through different coils at different times, this will create our rotating magnetic field. However, the capacitor must be sized correctly to achieve this.

We covered the basics of capacitors in detail in a previous article, check it out here.

Multi-speed motor windings

We usually have a switch on the side of the motor terminal that allows us to change the speed of the motor and therefore the flow rate of the pump, as well as the discharge pressure.

Inside the motor, the operating coil will have several connection points, or there could even be several different coils. The switch makes it possible to connect to these different points and effectively modify the length of the coil through which the electricity must pass.

You may be wondering why the low setting has a longer spool than the high setting.

When we pass an alternating current through an inductive coil, the magnetic field it generates interferes with the electrons trying to pass through it. A force known as inductive reactance opposes the change in current.

As we increase the length of the coil, the inductive reactance also increases, which makes it difficult for the current of electrons to pass through. Therefore, as the current decreases, the electromagnetic field also decreases, which reduces the speed and torque of the motor.

When we switch to the lowest setting, the inductive reactance is maximum, the current is reduced, and the motor rotates slowly.

When we go to the high setting, the inductive reactance is minimal, so the current is high and the rotor spins much faster.

We covered multi-speed pushups and how to read your pushup charts in our previous article. Check that here.

How does a circulation pump work?

So how does the circulation pump work? First, the water from the hot water system enters the pump through the inlet and enters the impeller eye, this water will be trapped between the impeller vanes inside the pump body.

Electricity enters the terminal box and flows through the motor windings, the capacitor helps create a rotating magnetic field, and this magnetic field forces the rotor to rotate. Attached to the rotor is the shaft. The shaft runs from the motor to the pump casing where it connects to the impeller.

When the rotor turns, the shaft and the wheel also turn. As the wheel turns, it imparts kinetic energy or velocity to the water, and the water moves outward.

The water increases in speed and kinetic energy as it reaches the edge of the wheel.

By the time the water reaches the edge of the wheel, it has reached a very high velocity. This high velocity water fly leaves the impeller and enters the volute where it strikes the wall of the pump body.

This impact converts velocity into potential energy or pressure.

The water impacts the pump casing. Kinetic energy is converted to potential energy (pressure).

|

| water impact pump body |

As the water moves out and out of the impeller, this will create a region of low pressure in the center which draws in more water and thus a flow develops. The volute channel has an expanding diameter as it wraps around the circumference of the pump body. As it increases, the velocity of the water decreases, causing the pressure to increase.

More water follows behind; flow develops. The diameter of the volute channel increases; this causes the velocity of the water to decrease, which increases the pressure.

Therefore, the expanding channel allows more water to continue to join and become pressured.

Thus the discharge outlet is therefore at a higher pressure than the suction inlet. The high pressure at the outlet allows us to force the water through the pipes and remove it when and where it is needed. Ok guys, that's it for this video, but to continue your learning, watch one of the videos on the screen now and I'll see you there for the next lesson. Don't forget to follow us on facebook, instagram, twitter, linkedin as well as engineering mindset .com

Do you need help maintaining and repairing an air conditioner?

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦TAGSIt's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

- #pump

- #pump_design

- #pumps #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment