Keep Your Chiller Running Properly with Regular Maintenance

LTD Analysis/Tube Cleaning

Increase chiller efficiency with tube inspection

Leaving Temperature Difference (LTD) analysis improves chiller performance and efficiency by verifying tube cleaning time and providing guidance to the customer for water quality management.

LTD Analysis

LTD lift is an index that indicates if the heat exchange performance of your tube cooler is deteriorating (LTD management criteria: below 3°C).

tube cleaning

Scale inside the heating tube interferes with heat transfer, reducing the life and efficiency of the device, therefore periodic cleaning is necessary.

benefit of

benefit of

Better performance and lower power consumption improve the reliability of your cooler (actual values for improvement may vary by site).

Ensure the reliability of the internal parts of the compressor.

Oil change and analysis

The replacement cycle is analyzed by oil differential pressure analysis and replaced with pure LG oil to ensure parts reliability. Oil analysis can be added upon customer request.

benefit of

PPrevention of damage to major components due to lack of lubrication

Propose suitable compressors for better operation

Discharge Overheat Analysis

Site load analysis by analyzing the number of times the upper and lower limits (3 - 10°C) of discharge superheat are reached.

Annual analysis of operating areas

Analysis of operating zones by chilled water temperature and cooling water inlet.

benefit of

Provide suitable compressor and stable operating environment to ensure reliability and energy saving. (A: Inverter, B: High Head Comp, C: High Capacity Chiller/High Head, D: High Capacity Chiller)

Prevent damage with early failure detection of rotating parts

Data-driven vibration analysis

Failure prediction through vibration trend analysis.

Note) A: Bearing oil temperature / B: Oscillation Vibration

Spectral analysis of vibrations

Fault prediction by Hz spectral analysis.

benefit of

Extend compressor life and reduce overhaul costs and downtime by preventing compressor failure.

Safe compressor integrity with surge prevention logic

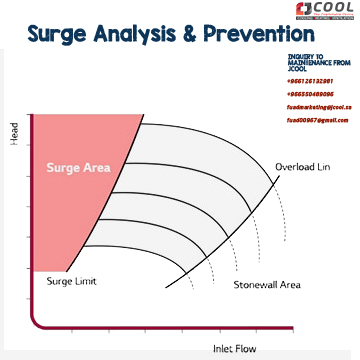

Surge analysis

The moments of surges that occur in the compressor are analyzed.

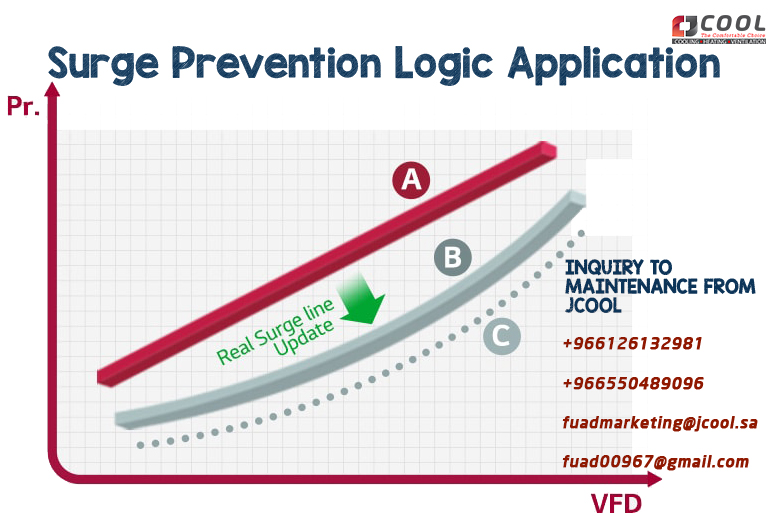

Surge Prevention Logic Application

Overvoltages are prevented by resetting the self-learning surge lines.

Note) A: Early surge line / B: Actual surge line / C: Map surge line

benefit of

Prevention of damage to compressor components, energy reduction and stable operation of the product.

Improve heat exchanger performance and cooler integrity

Analysis of absorbent components

The analysis checks for absorbent alkalinity that can lead to scale development and checks for the proper amount of corrosion inhibitors.

absorbent purification

Purification of the absorbent solution by filter or ionic method.

benefit of

Energy saving and longer life of the cooler.

Comments

Post a Comment