Learn about pump curves, how to read them and what the different lines mean.

Scroll down to see the YouTube tutorial

Learn more about pump curves, how to read them, and what the different lines mean.

State Supply is your source for les composants de sistèmes de chauffage à vapeur et hydroniques, tels que les purgeurs de vapeur, les vannes, les commandes et les pompes (y compris la meilleure marque de l'industrie such as Bell & Gossett, Taco, et Plus). Visit www.statesupply.com

Discover centrifugal pumps ➡️ https://www.statesupply.com/pump/hydronic

Watch pump repair and maintenance videos➡️ https://www.youtube.com/statesupply

Download this guide ➡️ https://www.statesupply.com/boiler-inspection-checklist

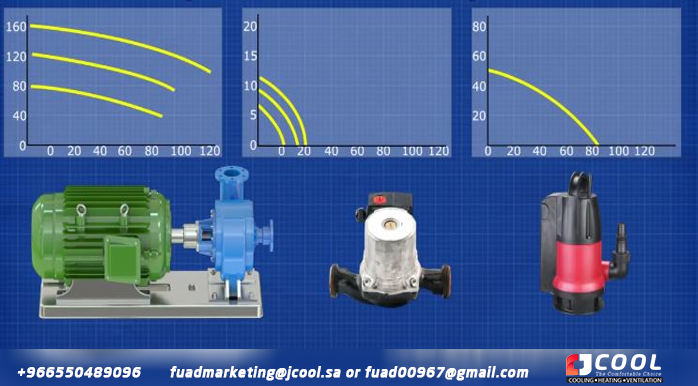

Basic pump curve

The basic pump curve looks like this.

They get more complicated and look something like this. Don't worry, we'll go through them step by step and start with the basics.

Each type of pump has a different graph and the data plotted on these also varies by model.

|

| Pump Table Differences |

The first thing we notice is that on the main vertical Y axis we have discharge pressure and on the horizontal X axis we have flow.

Basically the head is the pressure and the flow is the amount of water the pump can move.

What do these graphs represent? If we turn the pump on its side and connect it to a pipe. The pump pushes the liquid horizontally, so there is no pressure, but the water is flowing at its maximum speed. As the pump is slowly turned to the vertical position, the flow rate decreases but the pressure increases. This is because it is now pushing against the water and friction. When we reach the vertical position, no water comes out of the pump but maximum pressure. This is because it uses all its energy to push the water and keep it as high as possible in the pipe. At this point you're just spinning the same amount of water which isn't good for the pump, so you don't want to run a pump like this in the real world. By recording the values during this rise, we basically get our yield curve. Although we do note that bomb makers do not test bombs this way as it is not practical.

If you want to know how a centrifugal pump works, we covered it in detail in our previous article. CLICK HERE.

head pressure

The head is shown on the vertical axis and this refers to pressure, which is why we often hear the term head pressure. We measure the head in feet or meters, which does not seem correct considering that we are talking about pressure. Especially since you see the pressure gauges on the pump that usually read psi or bar. The reason for the feet or meters is that pump manufacturers only know how high their pump can push a fluid, they don't know what fluid their system will pump, and since each fluid has different properties, the pressure will vary depending on the fluid used, but the height to which it can be moved by the pump will remain the same.

For example, we have this pump that can provide 150 feet of head. If we use it to pump water, the pressure will be around 54.25 psi (4,485 bar). But if we use it to extract milk, the pressure will be around 56.15 psi (4.64 bar).

Converting between feet and head meters is easy, we have a free calculator for that, CLICK HERE.

Why do we need to know head pressure?

Pumps are usually used to move liquid to a higher region, so we need to make sure our pump can reach that altitude. When we pump liquid through pipes and fittings, friction will try to oppose the flow. This is due to the walls of the pipe and also to disturbances in the flow path causing a loss of pressure which wastes energy from the pump. The amount of friction depends on the type of fluid, as well as the materials and accessories used. So we need to calculate how much friction or pressure loss our system will generate and make sure the pump we select can overcome this, otherwise we won't get any fluid at the other end.

When we look at the graphs, we find pumps that vary in height and flow. For example, when looking at a small home heating system, there are some short pipes and fittings, so there is not much pressure drop, so we would use a pump with a relatively low head pressure.

When we look at a commercial heating system with multiple AHUs, fan coils and long piping, we know that the pressure drop will be high, so we would need a pump that can deliver much more head pressure.

Debit

Flow rate is a measure of the amount of water that flows from the pump in a given period of time. This is measured in different units, for example, gallons (US) per minute, liters per second, or cubic meters per hour. For example, a system can be designed to move 2 liters of water per second (31.7006 US gpm) from a storage tank to a treatment tank.

You can easily convert between metric and imperial units for flow with our free calculator, CLICK HERE.

performance curve

This is sometimes called the H-Q curve. H stands for head and Q stands for flow. The manufacturer will test each pump for performance data and then plot it on the graph. This will represent all possible configurations between flow rate and discharge pressure and we use it to check if a pump will meet our needs.

The performance curve will be different for every pump and some will meet our system needs better than others. You will generally see that as the flow increases, the discharge pressure decreases.

When selecting a circulation pump, the pump will only work according to the line. So if you need 8 GPM (0.5 L/s), you will be 6 feet (1.8 m) tall. You can also get multi-speed circulation pumps, which we'll talk about later in this article.

When selecting a larger centrifugal pump, as long as our system requirements are at or below the performance line, the pump can be considered. Potentially we can use smaller wheels or VFDs to better suit our needs and again we'll get to that a bit later in the article.

For example, here is the performance curve for 2 large centrifugal pumps. We need a flow rate of 30 gpm (1.89 L/s) and a head pressure of 70 ft (21.3 m), which is shown here on the graph. This means that bomb 2 cannot be used, but bomb 1 could.

impeller size

With centrifugal pumps, we can often change the size of the impeller. The diameter of the impeller will change the amount of water that can be moved. So in some graphs you will see various performance curves that give us the details of pump performance for different impeller diameters. The wheel size will often appear at the end of the line.

For example, 30 gmp (1.89 L/s) for a 4.5 in (114.3 mm) impeller gives us approximately 13 ft (3.96 m) of head, but if we were to use a 5.5 in. inches (139.7 mm), we should get about 22.5 feet (6.89 m) of head.

In some cases, the required flow rate and discharge pressure may fall between the two impeller bore lines. In such cases we can often machine the wheel to the required size to achieve a better match. You should have the pump manufacturer or a pump specialist perform this service. Next, the efficiency of the pump must be calculated.

pump power

As we know, pumps require mechanical power to turn the shaft, the rotor, and ultimately move the water. Pump manufacturers often provide a separate chart that plots this power requirement. In imperial units we use brake horsepower and in metric units we use kilowatts.

With this graph, we see the braking power plotted at different intervals. As you can see, as performance increases, the power required also increases. We use this table to size our motor. For example, if we needed 125 gmp (7.89 L/s) with 18 feet of headroom (5.49 m), that would be between 0.75 (0.559 kW) and 1 horsepower (0.746 kW). Since this point is above the 0.75 line, it means you can't use a motor of this rating because it's not going to be able to cope, you'll need to switch to a 1 hp motor and you see the performance curve drop by complete. below this line, so if our discharge pressure calculation is incorrect, we have a margin of safety.

pump power table

If you want to convert between brake horsepower and kilowatts, check out our free calculator, CLICK HERE

Efficiency

Some graphs show the efficiency curve of the pump. This is measured in percentages and we usually see this parabolic curve where the pump increases its efficiency to its maximum and then starts to decrease again.

Charts showing different wheel sizes will generally show efficiency on these more complex scribble lines. Each line shows the percentage of efficiency.

Charts showing different wheel sizes will generally show efficiency on these more complex scribble lines. Each line shows the percentage of efficiency.

|

| efficiency display |

In both graphs you can see that the efficiency varies depending on how you use the pump. In multi-impeller diagrams, we see that efficiency decreases as the impeller size decreases, this is because the gap between the impeller and the pump casing increases, so water can flow through it. region and therefore energy is wasted.

Efficiency is the ratio or comparison between the amount of energy going into the pump and the amount of energy we get out of the pump. So ideally we want to be as close to the peak as possible for optimal performance

|

| Efficiency is the ratio of the energy entering the pump to the amount of energy leaving the pump. |

The pump will inevitably lose power as it converts and transmits electrical energy into mechanical energy. This will leak through the coupling, bearings, shaft, seals, cooling fan, etc. For example, in this graph, we can see that if the pump were delivering 125 gmp at 20 feet, it would be running at about 67% efficiency, which it isn't. is very good. If the same pump were running at 30 ft head 138 gmp it would be running at its 73% max efficiency which is better.

|

| Pump Efficiency Example |

NPSH

We talked about NPSH in our previous article. This is the required NPSH or Net Positive Suction Head Pressure. It usually has an upward curve, which means that as the pump flow increases, we also see the NPSH value increase. We measure this in meters or feet, sometimes in kilopascals.

|

| NPSH |

NPSH is the minimum pressure that must be available at the pump suction inlet to overcome inlet losses and prevent cavitation. Therefore, the available pressure at the inlet must be greater than this value. In short, cavitation is when the pressure at the pump inlet drops enough that the water begins to boil, creating air bubbles that rapidly expand and collapse, gradually destroying the pump surface and casing.

|

| cavitation |

For example, if we are moving at 150 gmp(m), we need an NPSH of approximately 4.9 ft (1.49 m).

Multi Speed Pump

|

| single speed circulation pump |

Some bombs like the one above; They run at a fixed speed and therefore have a fixed performance curve, but we can also get multi-speed versions that have the ability to switch between speed settings, usually with 3 different speeds, low, medium and high. So these bombs will have a board with three different profiles drawn on it.

We can run the pump on any of these curves but not between them. So for this example, if we want 6 gallons per minute or 0.38 liters per second, on setting 1 we get about 4.2 feet (1.28 m) of head, on setting 2 we get 8 feet (4.44 m) high and in configuration 3 we get approximately 9.8 feet (2.99m).

|

| Example of a multi-speed circulation pump |

These pumps allow us to easily improve our match between pump performance and system requirements or allow for future system expansion.

Variable Frequency Drives/Variable Speed

Another option we have is to use frequency or variable speed drives. This basically takes the power supply and modifies it to reduce voltage and frequency, which therefore modifies motor power and pump speed. We can increase or decrease speed via the controller to improve our pump mix and thus operate almost anywhere in the region below the curve.

They are really only used on larger pumps, usually over 2 kW (2.7 BHP). They may come pre-installed with the pump's motor, or you can often retrofit an existing pump, but you should check with the manufacturer first to ensure compatibility. Also, you should check the system design to make sure it can handle the lower flow rate or discharge pressure. To get the performance details of variable speed pumps, we need to calculate the values using the pump affinity laws. We have covered this previously in worked tutorials, CLICK

HERE.

rotational speed

Some pump manufacturers will provide separate tables for running the pump at different RPMs. We can then compare performance to get a close match and then find an electric motor that fits. In general, higher rotation speeds result in more care and maintenance. Whenever possible, it is recommended to choose a lower speed pump that meets the requirements of our systems.

voltage and frequency

Check the specifications of the electric motor. Mains voltage and frequency vary around the world, so you need to make sure that the pump you select will work where you install it. Additionally, the pumps are available in single-phase and three-phase models depending on the application. These details will be provided by the manufacturer and will normally be on the drawing or technical document.

|

| Voltage and frequency differ |

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #pump

- #pumps #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment