The Basics of Liquid Level Switches Explained

Find out how and where liquid level switches are used in ammonia industrial refrigeration systems. We will see the main parts, the applications and the internal technology.

Scroll down to see the YouTube tutorial

🎁 See the Danfoss LLS 4000 HERE

Time to move on to electronic liquid level switches. The Danfoss LLS 4000 Liquid Level Switch greatly facilitates commissioning and installation, and its SIL2 rating ensures its reliability. In addition, you can commission and monitor the switch using the new Danfoss smartphone app.

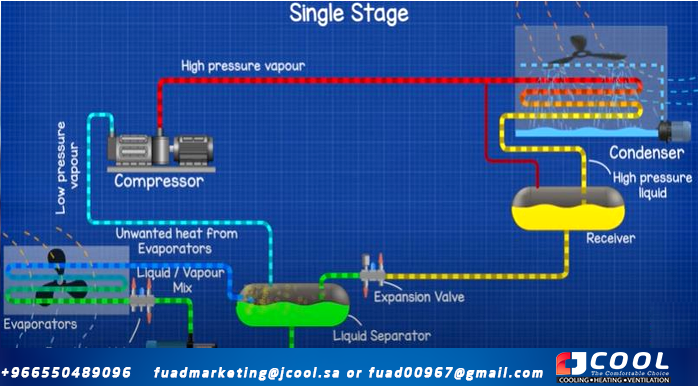

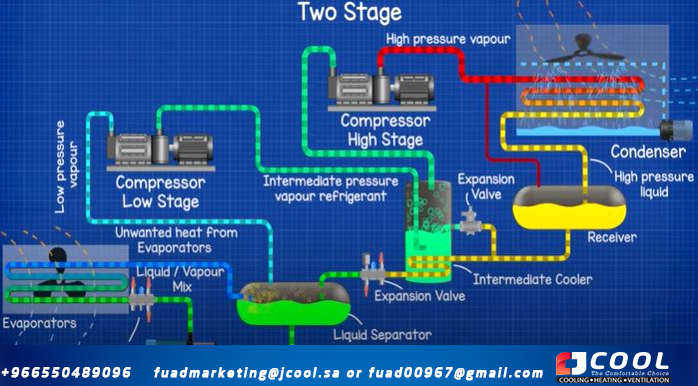

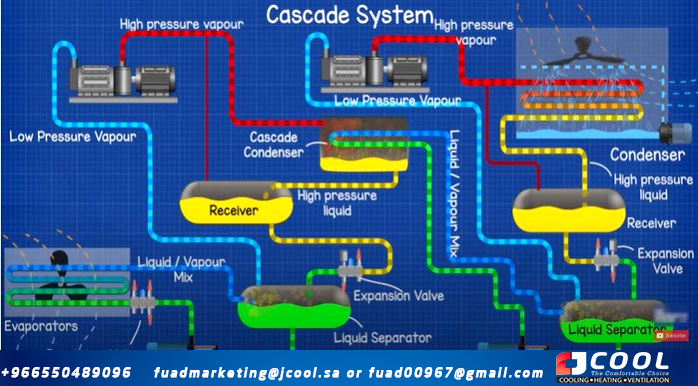

So, in our first article on industrial refrigeration, we looked at the main system components for single-stage, two-stage, and cascaded systems. If you haven't read this article yet, you can find it HERE

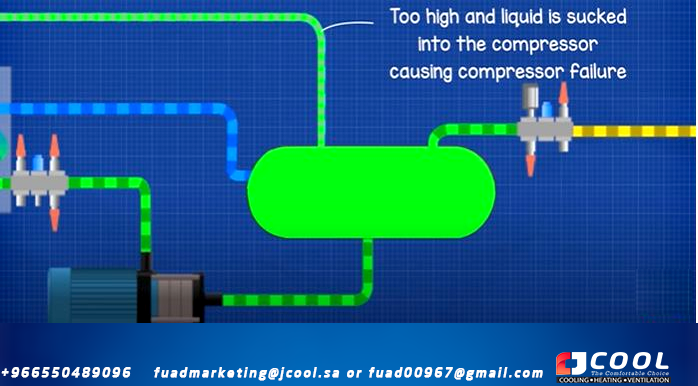

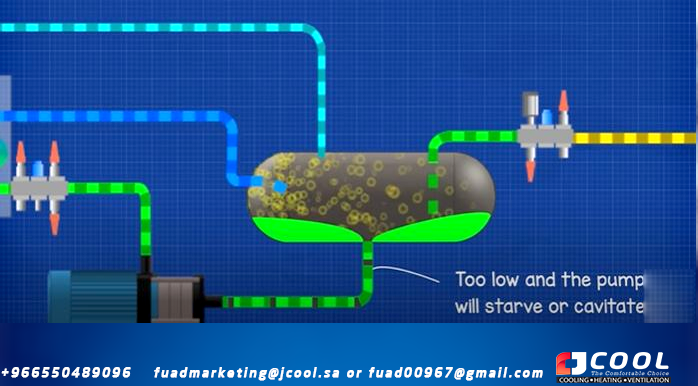

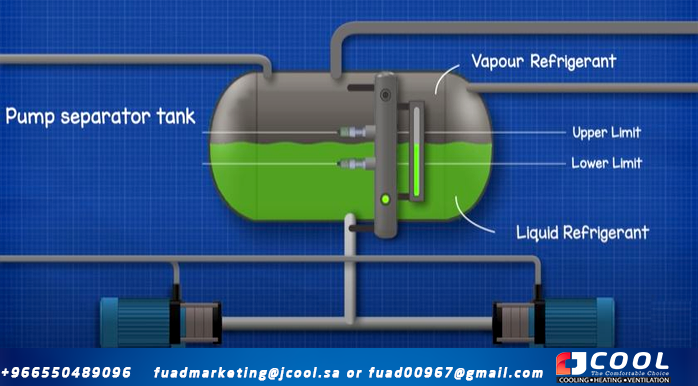

In each of these systems, we have seen multiple vessels that collect and release refrigerant to keep the system running smoothly. In these containers we have a mixture of liquid refrigerant and vapor refrigerant. The liquid level rises and falls during system operation and the cooling demand experienced by the system. Now we don't want the liquid level to get too high or too low in these vessels, we need to keep the level between our set upper and lower limits for the system to work properly. If we don't maintain that, we're going to run into all sorts of problems.

The containers and pipes are made of metal, so we cannot visually see inside. We can install sight glasses and fluid level gauges, but these will require constant manual readings. We need an accurate and autonomous way to detect if and when the liquid level is within limits, and automatically alert engineers to the problem.

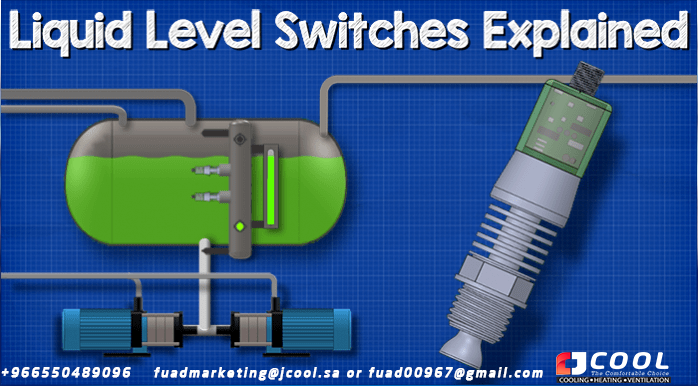

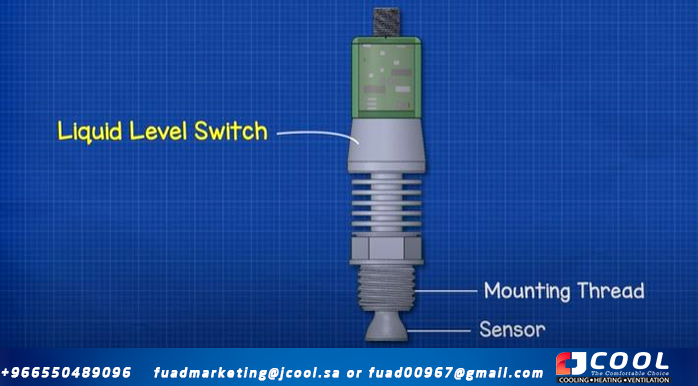

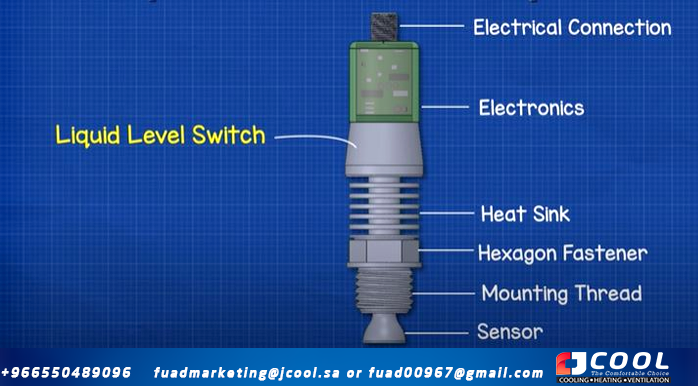

So for this we use digital liquid level switches that look like this.

At the end of the unit we have a sensor, we will see in detail the operation of this part later in the article, but this part will be in contact with the refrigerant. Next we have a cable that will allow us to connect the device to the system and seal it in place. There is a hex head just above the one we use to tighten the device into our system fitting. Next, we have a heat sink that is only going to dissipate unwanted heat from the electronic components. We want to remove that heat to ensure electrical components last a long time and don't overheat. These fins just increase the surface area and allow us to dissipate more heat. in ambient air. Connected to this we have the electronic circuit board that has a protective casing and at the top we have the electrical connection that will power the device and allow electronic communication with the system controller.

How and where are LLS used?

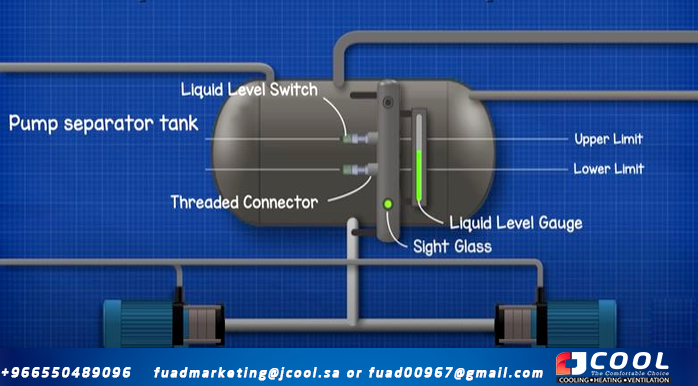

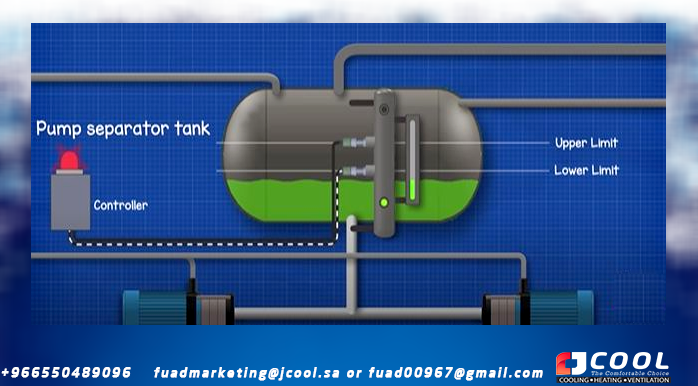

Let's say for example we have this pump separator tank in our ammonia refrigeration system. We want to make sure that the ammonia coolant fluid level stays between an upper and lower limit.

Mounted on the side of the ship we have a column; We'll probably find built-in sight glasses on this and we might even have a column-mounted liquid level indicator. Both simply allow us to visually inspect the level of liquid refrigerant in the tank.

|

| Pump separator tank components |

In the column we have two threaded connectors in which our liquid level switch will be screwed. These are placed between the upper and lower limits of our tank for the liquid level we wish to maintain.

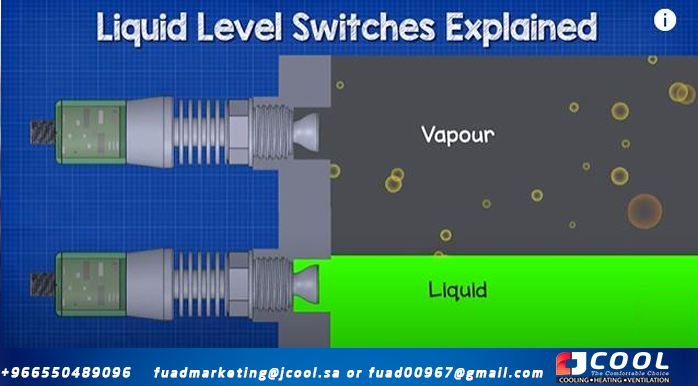

So as we can see the lower level switch is immersed in the liquid refrigerant while the upper switch is in the region of the vapor refrigerant. This is what we want, because it means that the liquid level is within the desired limits, so the system works normally.

The device detects the difference between liquid and gas, so when installing the device we must be careful about the possibility of gas pockets. For example, if we install the device in a horizontal position, as the liquid level rises and falls, any pockets of gas will naturally dissipate. But if we install the device vertically, it is possible that gas is trapped in the enclosure. Obviously, this will affect the sensor reading and we will not get accurate results.

We have already covered purging cooling systems with ammonia, you can find it HERE

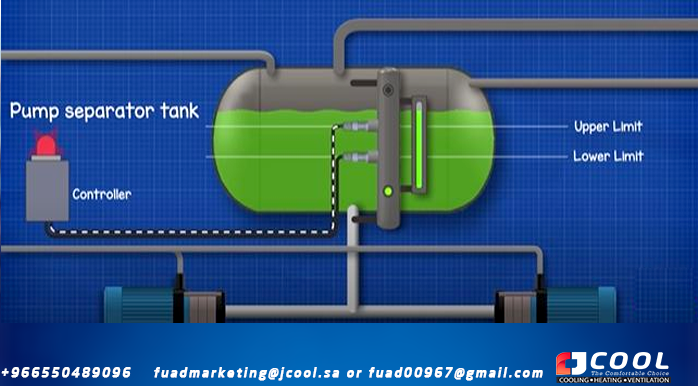

Let's go back to the installation of the column. We might face the problem that the liquid level drops, in this case the liquid level will drop below our lower limit switch. The sensor will detect this phase change from liquid to vapor and send a warning signal to the system controller.

Also, we may face the problem of overfilling when the liquid level rises too high in the container. This means that the liquid refrigerant will rise above the upper sensor. This sensor will also detect that there has been a phase change from vapor to liquid and will again send a warning signal to the system controller.

In either case, the switch activates a built-in relay that is used to activate an alarm and can be connected to the PLC system or programmable logic controller.

How does LLS work?

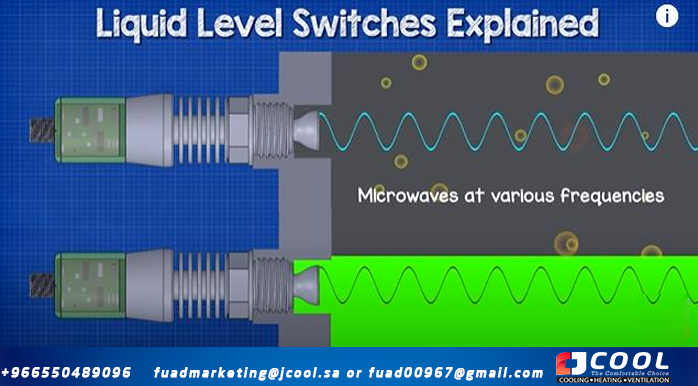

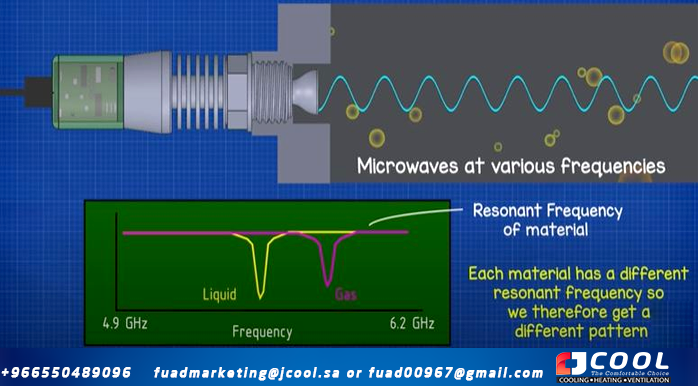

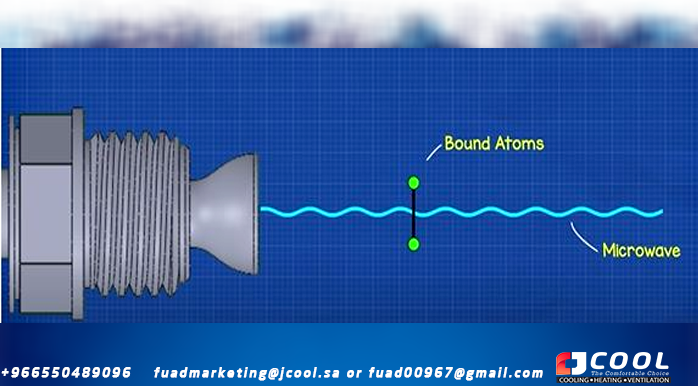

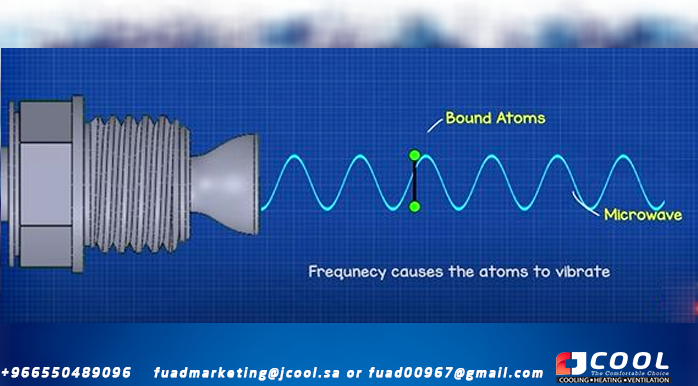

The device uses a technology known as reflectometry that emits microwaves at different frequencies from the sensor into the fluid, bouncing off the sensor in a pattern. Each fluid and the different states of the fluid create a different pattern.

The pattern is the resonance frequency of the fluid and each material has a different resonance frequency so we get a different pattern. Liquid has a much lower frequency than air, so we have these different graphs.

The resonant frequency is the frequency that causes the atoms of the material to vibrate. So looking at a very simplified example, the sensor emits a microwave at a certain frequency on some atoms that are bound together, this frequency has no effect on the atoms and they don't vibrate. But as we vary the frequency across a spectrum we find a frequency that makes the atoms vibrate, as we go across the frequency spectrum the vibration stops. So by measuring these vibrations of the atoms over a spectrum of frequencies, we can plot this pattern.

Various refrigerants are tested and the manufacturer stores the results in the device. So once we have configured the device and specified the refrigerant used by our system, the device can correlate its measurements with known properties and thus we have our digital liquid level switch that can detect liquid or vapor and transmit an alarm if the system fails. .

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #industrial_engineering

- #industrial_refrigeration #

- refrigeration #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment