Learn how evaporators and controlled in industrial refrigeration systems, covering defrost, cooling, drip tray, valve stations, controller, liquid line, wet return line, hot gas line, vapour line, compressor, liquid separator, evaporator and much more.

Learn how evaporators are controlled in industrial refrigeration systems, covering defrost, cooling, drip pan, valve stations, controller, liquid line, wet return line, hot gas line, vapor line, compressor, oil separator. liquid, evaporator and much more.

Scroll down to see the YouTube tutorial.

Industrial refrigeration systems are among the largest and most complex in the world. These systems produce large amounts of cooling and to achieve this they require many evaporators, each requiring a series of complex-looking valves.

Controlling these systems can be challenging. Engineers have to make sure that the system works efficiently but also efficiently. To do this, we must be able to communicate with and control the various components of the system. So how do you get there?

Well, we need a controller. This is the EKE 400 from Danfoss, who kindly sponsored this article.

We'll look at the purpose of the controller, covering the basics of what it connects to in the system. But I've partnered with Danfoss for this article, and they'll walk you through the technical side with in-depth discussions of controller installation and features to help you develop your technical knowledge and understanding of not just controllers, but refrigeration as well. . systems. You can check it here:

System

|

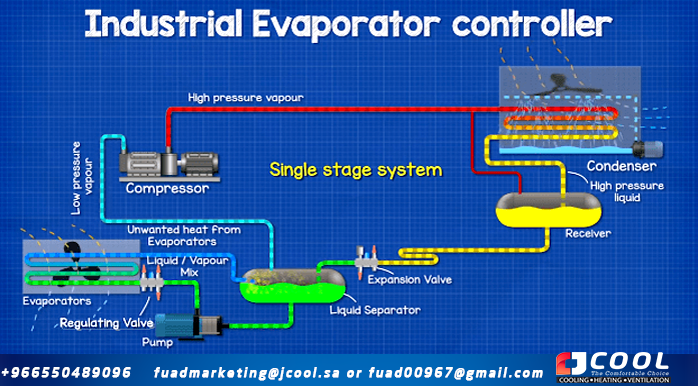

| single stage system |

If we look at a single stage system, which is the simplest industrial refrigeration system, we can see that we have the different components of the system like compressor, condenser, receiver, liquid separator and in the corner, we have the evaporator. We will focus on this section in particular.

So here we have a more detailed version of the evaporator circuit.

As you can see we have the evaporator and fans that blow ambient air through the evaporator heat exchanger to capture unwanted heat from the room and exchange it for cooling.

Next we have the liquid supply line. This comes from the liquid separator and is circulated by a pump. The refrigerant is in a liquid state and flows through the valve station and then to the evaporator. The refrigerant is held in the tube walls inside the heat exchanger, cannot escape to the atmosphere, and does not mix with the surrounding air. Inside the evaporator, the refrigerant will pick up unwanted heat as it absorbs that heat and becomes a mixture of liquid and vapor. The refrigerant then leaves the evaporator and flows through the wet return line, through another valve station, and back to the liquid separator. From there, the liquid will go back to the pump while the vapor will go back to the compressor.

|

| Basic refrigeration circuit |

This is our basic evaporator cooling loop. Refrigerant is pumped through the loop to remove unwanted heat and therefore provide cooling.

Defrost

Due to the temperature difference between the air and the refrigerant inside the evaporator, the air condenses and the moisture in the air freezes in the heat exchanger. This decreases the efficiency of the heat exchanger, so we have to defrost the evaporator from time to time.

|

| Ice decreases the efficiency of the evaporator |

So we have another line coming in, this one comes from the compressor outlet and branches off to feed the different evaporators. This high pressure vapor refrigerant will pass through a valve station, through a drain pan, and then through the evaporator in the opposite direction.

This effectively turns the evaporator into a condenser. The hot refrigerant will melt the ice and it will collect on the drip tray as we don't want it to fall on the floor as it will refreeze very quickly.

As the refrigerant exchanges its heat with the ice, the refrigerant condenses into a liquid. This liquid refrigerant will leave the evaporator and flow into the liquid supply line. The supply line valve station is closed for refrigerant to flow to the de-icing liquid drain line and another valve station controls the flow through here, usually using a float valve. From there it returns to the wet return line and enters the liquid vapor separator where the refrigerant can flow to the compressor or back to the evaporator.

When defrost is complete, the valves are reversed and cooling resumes.

Here is our basic refrigeration circuit with hot gas defrost.

controller connections

Now we need to be able to control all of these valves, along with other components. This will allow optimal system operation as well as control of the defrost cycle. So our driver is installed and we run some connections. We first connect to the solenoid valves at each of our valve stations, on the liquid line, the wet return line, the hot gas line, and the drain line. This will allow us to automatically control the position of each valve during normal operation and the defrost cycle.

We can also use other defrost methods, such as electric defrost, water/brine defrost, as well as hot gas defrost by pressure control or liquid drain. But I will not cover them in this article.

Next we also want to connect the evaporator fans to the controller. This will allow us to control its rotation speed based on the cooling demand. Since we are exchanging thermal energy, we also need feedback, so we will also connect a temperature sensor to the controllers. In addition, we can also connect a gas detector to the controller for added security.

By the way, we have also covered the different types of industrial refrigeration systems in our previous articles. Check them HERE.

There will probably be multiple evaporators in the refrigeration system, so we will need to install a controller for each individual unit. However, we can connect each controller to each other, this will allow us to coordinate a defrost, this also allows us to use a centralized temperature sensor. Alternatively we could connect the controllers to a PLC, this would allow us to remotely monitor each evaporator. Again, we can coordinate defrosting through this method.

Once installed, we must take into account the defrost activation parameters, superheat control, air temperature, etc. This device comes with a built-in wizard to speed up and simplify setup. But for that, I'll redirect you to Danfoss for part 2 of this article HERE.

So using the controller, we can:

· Reduce costs and installation time

· Get optimal refrigeration mode and safe defrost sequence

· Increase design flexibility

· Control valves and fans for individual evaporators

· And we can also change the measurement units and language settings based on the local installation.

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment