Multi Ejector CO2 Transcritical Systems

How multi-ejectors work in transcritical CO2 refrigeration systems. In this article, we are going to discuss the multi-ejector and its application and working principle for transcritical CO2 refrigeration systems. We will cover the basics of RAC systems in Booster, Parallel Compressor and Parallel Compressor with integrated Multi-Ejector configurations.

Scroll down for video tutorial - includes full animations!

🏆 Learn more about the Danfoss Multi Ejector SolutionTM at:: http://bit.ly/Multi-Ejectors

When combined with Danfoss Multi Ejector SolutionTM technology, CO2 enables refrigeration systems to outperform traditional HFC systems in terms of energy efficiency in all climate zones, while reducing the impact on our environment – it's the ultimate in which everyone wins.

Now even the hottest regions like the Middle East, South and Latin America, Australia and Asia can enjoy all the benefits that CO2 has to offer. Learn more about what Danfoss says, "We love CO2" at ➡️ http://bit.ly/Multi-Ejectors

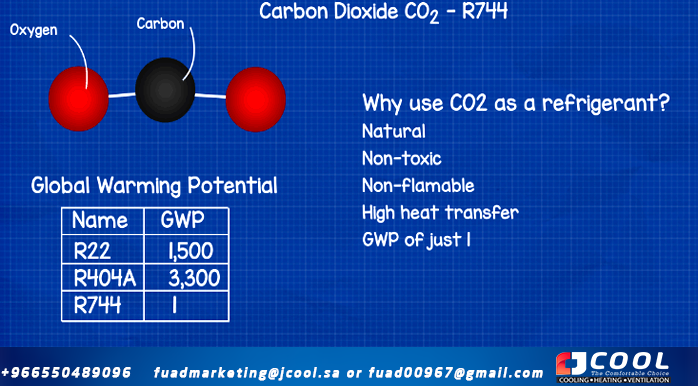

In a previous article, link here, we discussed how traditional HFC refrigerants are beginning to be phased out by new laws and regulations due to their adverse effects on the atmosphere and environment. This means that alternative refrigerants are used and there is a growing trend to use CO2 as a refrigerant, called R744.

|

| GWP of R744 |

R744 is popular because it is a natural, non-toxic, non-flammable refrigerant with high heat transfer and a global warming potential of only 1. It is gaining popularity, especially in supermarket or food store refrigeration systems, and many systems R404A and R22 are being replaced. . with R744 (CO2).

Traditionally, R744 has been used mainly in colder climates, especially Northern Europe, and that's because in colder climates it works very efficiently, whereas in warmer parts of the world where the ambient temperature is the same. or above 27 °C (81 °F) we find that historically R404A is more efficient than R744.

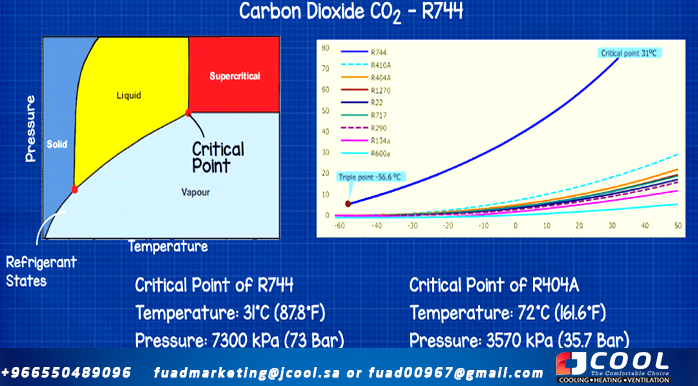

|

| critical point of r744 co2 vs r404a |

The reason why it was mainly used in Northern Europe is that the critical point of R744 is very low at only 31 °C (87.8 °F) and 73 bar (7300 kPa), whereas R404a has a critical point critical at 72 °C (161.6 °F) . F) and 35.7 bar (3570 kPa). Therefore, when the ambient temperature is near or above this low critical point, the refrigerant cannot undergo a phase change and condense to a liquid within the condenser. Evaporator cooling capacity is reduced, in a standard transcritical system, and higher gas cooler pressures are required to increase cooling capacity. However, Danfoss found a solution to the problem and launched the manifold ejector to allow transcritical CO2 systems to work efficiently even in the most difficult conditions.

Let's look at some simple systems to see where the multi-ejector is and how it works. We will consider the system operating in transcritical mode with an ambient temperature of approximately 33°C (91.4°F).

auxiliary cooling system

A typical first generation simplified CO2 booster system would be similar in design to a standard refrigeration system with the compressors compressing the refrigerant and sending it to the condenser or gas cooler to reject unwanted heat.

The refrigerant then passes through a high pressure control valve that controls the pressure of the refrigerant within the gas cooler. It then flows into the receiver which separates the refrigerant as to whether it is in a gas or liquid state.

The refrigerant that is in the gas phase will flow through a bypass line and valve to the compressor suction line where it will repeat the cycle.

Liquid refrigerant in the receiver will flow and take one of two paths, depending on the system design. In this example, the refrigeration system feeds both refrigerators and freezers, so we have two different pressure lines.

The first line is the medium temperature line that feeds the refrigerators. The refrigerant circulates through an expansion valve to the evaporator to provide cooling by removing unwanted heat, then it takes this unwanted heat and goes to the compressors.

By the way, if you want to know how expansion valves or evaporators work, we have already covered them in detail, link here.

The second line feeds the freezers and is therefore a low temperature/pressure line. Again this goes through an expansion valve and evaporator, but this time it goes to an additional compressor to build up the pressure a bit, then it will join the other refrigerant and flow to the main compressor to repeat the system.

In this design, 100% of the refrigerant flow leaves the gas cooler and enters the receiver, approximately 45% will be in the gaseous state and will flow through the bypass, while the remaining 55% will flow to the evaporators. Therefore, the main compressor has to work hard to try to compress 100% of the refrigerant through the system.

Parallel Compressor Refrigeration System

|

| Parallel compression system co2 transcritical refrigeration |

The second generation CO2 system added a parallel compressor that took the refrigerant in a gaseous state from the receiver and compressed it separately. In this design, approximately 45% of the refrigerant will enter the parallel compressor, while only 55% will enter the main compressor. This made the system more efficient because the gaseous refrigerant coming from the receiver is at a higher pressure compared to that coming from the evaporators, so less work is needed to bring it back to high pressure for the chiller. Of gas. The main compressor now only has to work with the remaining 55% of the refrigerant, so it also has a reduced workload.

Multi-ejectorTM solution

|

| Multi-ejector transcritical co2 refrigeration system |

The third generation design and the most energy efficient CO2 system design to date uses the multiple ejector with an AK-PC 782A package controller. In this design we run a line from the main compressor suction line and feed it to the manifold ejector. We also take the high pressure line from the gas cooler and feed it as well.

These refrigerants at vastly different pressures will be mixed together and delivered to the receiver. In this design, the manifold ejector will lift approximately 40% of the refrigerant from the main compressor suction line and mix it with the flow from the gas cooler. 60% of this mixture will go to the evaporators and 80% to the parallel compressor. So only 20% is compressed by the main compressor which has to work harder and the remaining 80% goes through the parallel compressor.

How the multi-ejector works

|

| Multi-ejector sectional view |

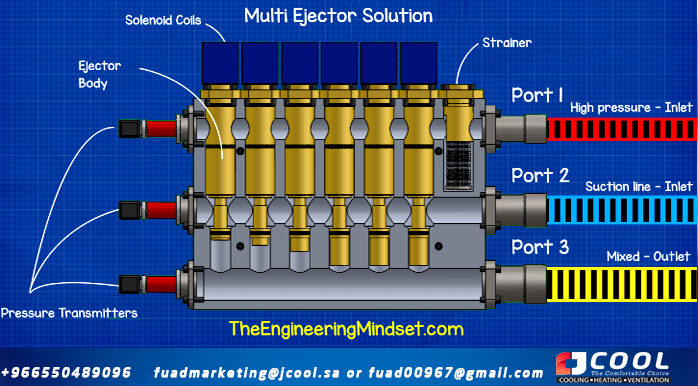

If we look at the manifold ejector you will see that we have 3 ports on the side, the top port is the high pressure inlet from the gas cooler, the center inlet port is the lower pressure inlet from the main compressor suction line. The bottom port is the outlet where the mixed refrigerant will leave the multi-ejector and go to the receiver.

On the other hand we have 3 pressure transmitters which are monitored by the controller.

Above we have a strainer through which all the refrigerant from the gas cooler will enter to protect the system.

Then we have 4-6 ejectors to control the flow of coolant through the manifold ejector, these are controlled by solenoid coils on top that are connected to the controller.

If we look inside the unit, we see the main body of the ejectors. The two inlet coolant streams enter the manifold ejector and are held in the headers. The controller will signal one or more solenoid valves to open to the required capacity.

|

| multi-ejector opening solenoid valve |

When the solenoid is energized, it lifts the respective valve needle to allow high pressure coolant to start flowing into the ejector.

|

| R744 refrigerant enters the manifold ejector |

It enters through the upper part that is known as the nozzle. The coolant then passes through a small contraction in the cross-sectional area known as the throat, causing the coolant to expand. During the expansion, the potential energy of the refrigerant at high pressure is converted to kinetic energy at high speed.

|

| CO2 R744 refrigerant gas entering the throat |

When the coolant reaches the nozzle outlet, it is at a very high velocity. As you will know from fluid dynamics, as speed increases, pressure decreases. This pressure reduction causes suction as the refrigerant passes through the second inlet port, this suction causes the check valve to open and then draws the gaseous refrigerant from the main suction line of the compressor.

These two refrigerants will then be mixed in the mixing chamber or mixing unit.

|

| Multi-ejector mixed refrigerant outlet |

The mixed refrigerants will then enter the diffuser which is conical in shape. This expansion of the cross section slows down the speed of the refrigerant and therefore the speed or kinetic energy is converted to potential energy or pressure. This medium pressure refrigerant then flows into the receiver.

Each drive ejector is rated for a different capacity, so the controller will vary the number and ejectors used to provide optimal performance.

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment