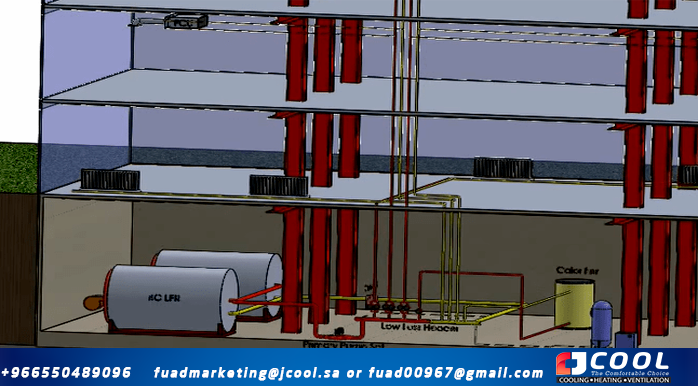

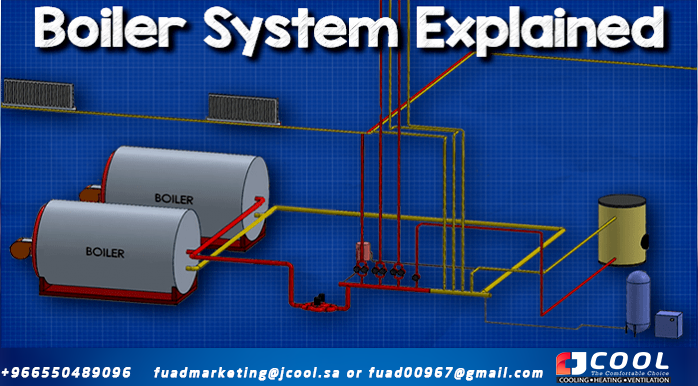

Explanation of the boiler system (LTHW). In this tutorial, we will look at a typical modern heating system in a commercial building. There are many configuration variations, but this version is fairly typical of newly built commercial buildings.

Scroll down for YouTube boiling systems tutorial

In this system we have two large boilers connected in parallel. This means that both boilers can work at the same time or individually. One of the boilers could be isolated and cycled for maintenance while the other boiler continues to run and provide heat to the building. This is the most common type of setup for modern heating systems. The other version would be daisy-chained, but that's an outdated design that's not as practical, at least for commercial offices.

|

| Example of different boilers |

Boilers are available in many designs, I gave a few examples above. It can be two large boilers or several smaller units. The best designs will use a mix of sizes to meet demand efficiently. Maybe a big one for the winter and a smaller one for the summer.

These boilers are the heat source for the heating system. This heat is transferred to the circulating water in the heating system which is then exhausted and around the building.

There are two terms you will find in these types of systems, primary and secondary circuits.

The primary circuit will circulate the hot water from the boilers and around the low-loss collector. The low loss header will supply hot water to the secondary circuits and then return the residual hot water from the chiller to the other end of the low loss header.

Primary loop water can flow directly through the low-loss header and back to the boiler to capture more heat, or it can return through the secondary loops. The routing of the water will depend on the demand for hot water from the secondary circuits. The water can flow directly because the boilers require a minimum flow to work, otherwise it may damage or destroy their internal parts.

The primary and secondary circuits will each have their own pump group.

Primary pumps tend to be larger pumps, usually of the centrifugal type driven by an induction motor. It depends on the size of the system, but they can also be of the inline type, especially in small office buildings.

Detailed explanation of the primary and secondary sides covered here

The primary pumps will only push water around the primary loop. This hot water leaves the boiler, enters this pipe, is sucked in by the main pump and then discharged in the low loss header.

|

| low-loss-header jcool |

This water can then exit through the secondary pumps off the low-loss header and flow to the risers, or some of it will continue to the other side of the header. In either case, the water will reach the end of the header and continue to flow, back to the boiler, but at a lower temperature to capture more heat and repeat this cycle.

|

| LTHW-Riser jcool |

Leaving the collector, on the hot side, are smaller pumps that are connected to pipes called risers. The risers ascend through the building to supply hot water to the different circuits. For example, the CTAs of the east or west wing. AHU’s.

In this example, we have four secondary circuits. Secondary circuits 1-3 are dual pump, and the 4th is single pump because its heating load is small and close, perhaps to the receiving area.

|

| Secondary-pumps jcool |

Above you can see an example of smaller secondary pumps. They can also be large centrifugal pumps, it depends on the size of the heating system. These pumps will force hot water where it is needed, but only for the selected area of the building to which the pipe has been connected.

Dual pump configurations generally run on duty and on standby. This means that one pump is running at all times while another acts as a backup pump in case the service pump fails.

Secondary circuits will supply water to a defined area of the building. For example, the first circuit can supply hot water to the radiators on the first floor. The second secondary circuit can supply hot water to the air handling units and fan coils on the east side of the building only, etc., etc.

After the hot water has passed through a heat exchanger and given up some of it’s thermal energy, it will return, via a return riser, where it will flow back to the low loss header and back to the boiler to pickup more heat.

domestic hot water

In this example, we also have a secondary circuit that goes out and feeds an accumulator. The accumulator is where the domestic hot water is produced, it is the hot water that comes out of the taps.

Why is domestic water separated from the hot water that is pumped around the building? There are a lot of chemicals that go into the main heating system of an LTHW system, a low temperature hot water system, and you really don't want to drink that.

Hot water is fed from the boiler to a secondary circuit where it will then be forced by a pump to a heat exchanger inside the accumulator. It will then transfer its heat to the fresh water that is held within the tank. This soft water will inevitably rise in temperature due to the heat exchanger. This heated fresh water is then piped to the kitchens, tea areas and bathroom sinks where it will be used and flow into the sewers. It will not return to the heating system. During this time, the hot water supplied, from the boiler, in the secondary circuit will leave through the heat exchanger inside the accumulator at a lower temperature, because it has given up part of its heat to soft water, and it will flow again to the low header. losses and back to the boiler.

pressurization unit

|

| Pressurisation-unit jcool |

Above you can see an example of an expansion tank and a pressurization unit. The pressure in the system will change, for example, if the secondary pump group is turned on, then the primary pump group will see a decrease in pressure, since more water is now flowing from the collector to the secondary circuit.

Similarly, if the temperature of the water increases or decreases, its density will change and this will also affect the pressure. Water expands when it gets hot and contracts when it gets cold.

The expansion tank and pressurization unit are connected to the main, usually somewhere around the low loss header. If the pressure gets too high, obviously the expansion tank will absorb some of it, and when it gets too low, the pressurization unit will force it back into the system to equalize it.

dosing system

|

| Dosing-pot jcool |

Above you can see an example of a dosing bottle. This is usually installed with thin tubing connected through the low loss header. This will then use the pressure difference to push hot water through it. The dosing bottle simply allows chemical inhibitors to be poured into the system, keeping it clean and free of bacteria.

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment