The basics of vacuum pumps explained.

Learn how vacuum pumps work, the main parts and why we use them. This article details the basic working principle of single and two stage vacuum pumps for HVAC engineers. For more articles on HVAC engineering CLICK HERE.

Scroll down to see the YouTube tutorial.

What are vacuum pumps?

Vacuum pumps are widely used by air conditioning and refrigeration engineers to remove air or non-condensables such as water from the system. We must remove them from the system because they lead to inefficient operation of the cooling system and can also corrode internal parts.

This procedure is done before charging a new system or when repairing an existing system where refrigerant has already been recovered. In either case, air and moisture may have contaminated the system.

Where are they connected?

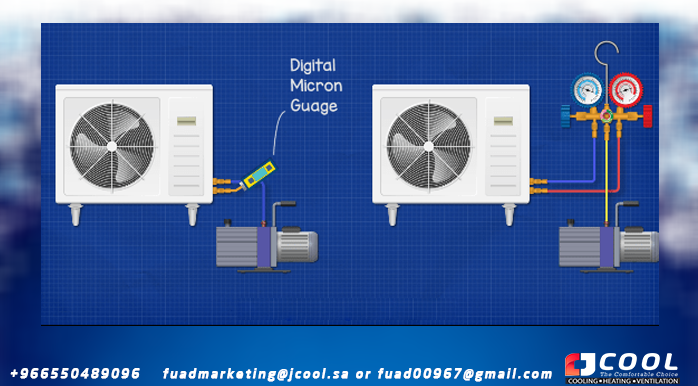

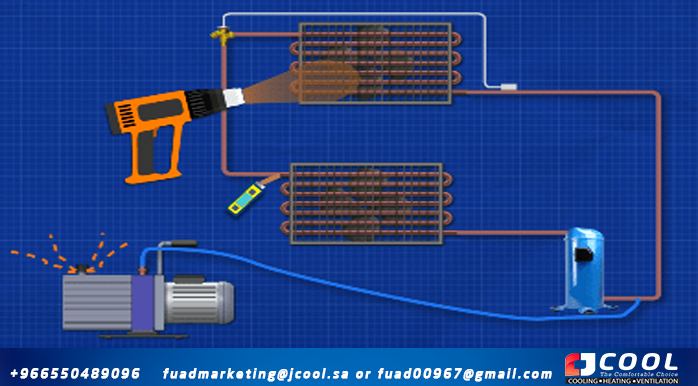

In a typical air conditioning system, you'll see these vacuum pumps connected through a manifold on the high and low pressure side of the system. A better way to do this is to remove the manifold and connect the vacuum pump to the suction line with a pressure gauge connected to the liquid line, as this is the furthest point in the system to get a true reading.

|

| Connect an indicator to the AC unit |

We teamed up with our friend Bryan at HVAC School for this article. His YouTube video shows you how to connect a vacuum pump to a real system and gives you lots of technical tips to expand his knowledge and skills. To view the YouTube video of him, CLICK HERE.

The main parts of a vacuum pump.

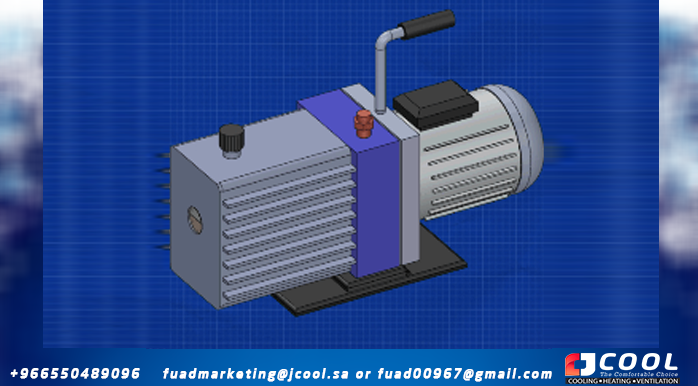

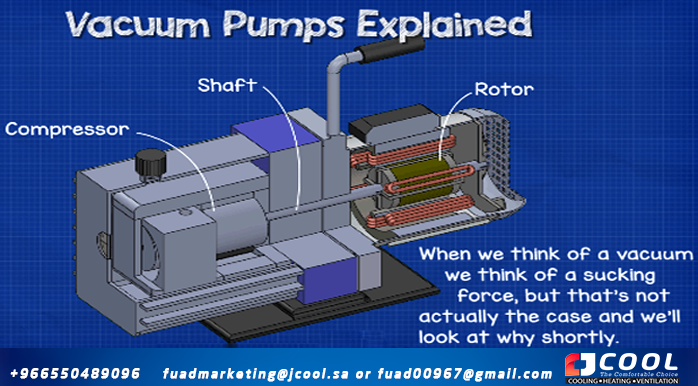

If we take a standard vacuum pump that looks like the following.

|

| Vacuum pump |

We have the electric motor at the rear, the compressor at the front, a handle at the top and a support base at the bottom. Then we have an inlet that connects to the system to remove air from the system and we also have the exhaust to disperse it to the atmosphere. On the front of the compressor section we will find an oil level sight glass so that we can determine the amount of oil in the chamber as well as its condition.

|

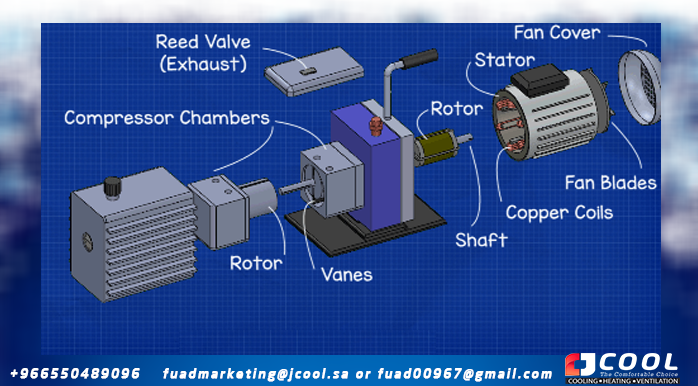

| parts of a vacuum pump |

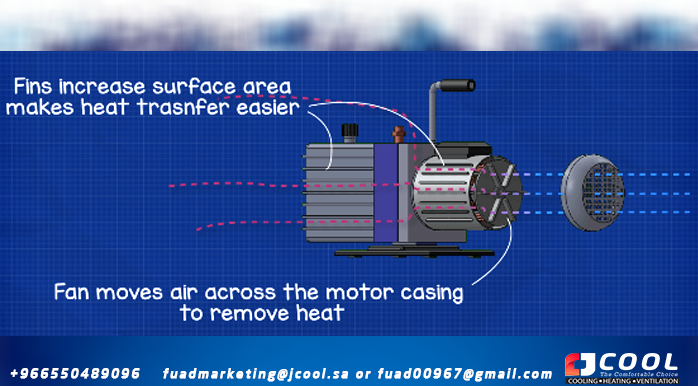

When we disassemble the unit we can see that we have a fan and a protective casing mounted to the rear of the motor. Inside the motor we have the stator with coils. Concentric to east; we have the rotor and the axis that moves the compressor. At the front we have the compression chamber. This is a two-stage version of the compressor that allows us to draw a deeper vacuum, so we have two compression chambers. Inside the chambers are the compressor rotors and the vanes that evacuate the air from the system. Above the compression chamber is a reed valve that vents the exhaust. When we remove the protective casing from the fans, we see that the fan is connected to the shaft that goes through the pump. The fan is used to cool the electric motor and will blow ambient air over the case to dissipate it. Fins on the shell increase the surface area of the shell, helping to remove more unwanted heat.

|

| Fins on the case help dissipate heat |

inside the engine

Inside the motor we have the stator that is wound with copper coils. When an electric current passes through the copper coils, it generates a magnetic field. The rotor is affected by this magnetic field and this forces it to spin. The impeller is connected to the shaft and the shaft runs its full length from the fan pump to the compressor. Here; As the rotor rotates, so does the compressor and this is what we use to create the vacuum effect and evacuate air from a system.

Just to note, when you think of a void; we think of a suction force but it is not really the case. We will detail why below.

inside the compressor

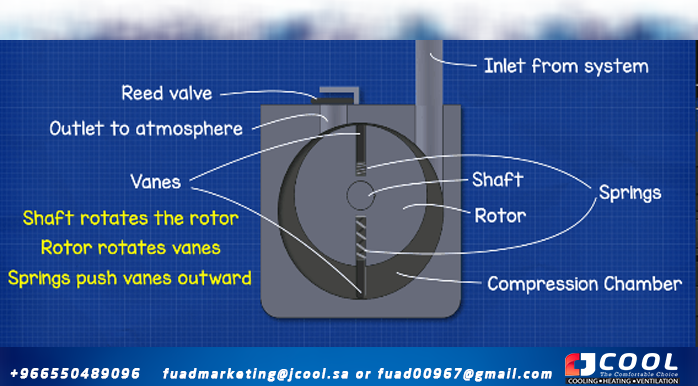

If we look inside the compressor we can see that we have the input, which is connected to the system that we are evacuating. Then we have the outlet and the seat valve that evacuates the air and the moisture that is extracted.

In the center we have the compression rotor and the compression chamber. Note that the rotor is eccentrically mounted within the chamber, meaning it is not perfectly centered, this is a key feature that we will look at in detail below. The shaft connects to the rotor and will make it spin.

Two spring loaded vanes are mounted inside the rotor. The springs are still trying to push the vanes, but the compression chamber walls hold them in place. The tips of the paddles are still in contact with the wall and there is a thin layer of oil that helps form a seal between the two. As the rotor rotates, the springs continue to push the vanes outward so that they follow the contour of the compression chamber.

|

| inside a vacuum pump |

When the pump starts, the rotor will move through the inlet exposing an area inside the compression chamber. This area will be at a lower pressure compared to the pressure inside the system; so air and moisture within the refrigeration system will rush in to try to fill that empty region.

Why does he do this?

Pressure always flows from top to bottom, so if we connect for example; two balloons of different pressures, the gases will move from the high pressure side to the low pressure side until both are at the same pressure. The low pressure side was a vacuum, but did not draw gases, the high pressure side sank. It is the vacuum effect. The gases want to balance and will go from high pressure to low pressure. The gases try to equalize the pressure in the connected regions. Therefore, we use a vacuum pump to create a region of low pressure for unwanted gases to

inside a refrigeration system it will rush out of the system to try to fill that region of low pressure.

In our scenario, the connecting pipe and the new low-pressure area in the compression chamber become an extension of the refrigeration system, so gases from the system will rush to fill it and try to equalize the pressure between the two. However, this is a cheat, because as the rotor continues to spin, the second vane sweeps up and traps that volume of gas in the chamber between the two vanes. The other vane passes through the inlet and creates another region of lower pressure, so more gas enters to fill that void over and over again. As the compressor rotates, the volume of the chamber will begin to decrease, so the rotor is not perfectly centered to vary the volume of trapped gases. This decrease in volume will compress the gases into a smaller space, which will increase the pressure and temperature.

It continues to rotate at a smaller volume until the pressure becomes high enough to force the reed valve on the exhaust open and the gases are vented.

The compressor continues to run, and as it does, the next batch of gas enters the system and this cycle continues.

Most vacuum pumps will be two-stage, meaning there are two compression chambers connected in series, with the exhaust from the first compressor connected directly to the inlet of the second chamber. This design allows the pump to achieve a deeper vacuum.

two-step design

When we have only one compressor; the outlet pushes against atmospheric pressure, as detailed above. But with the two-stage design, the outlet pushes against a much lower pressure that is simply the inlet to the second rotary compressor and the region of low pressure it creates during that rotation.

As the vacuum pump continues to run, it will eventually draw gases from the closed system, reducing the pressure below the pressure of the atmosphere surrounding the outside of the system.

|

| Heat lamp to remove moisture. |

As the pressure drops, any moisture in the system will be easier to boil off and evaporate. We can add some heat with a heat lamp or heat gun to help it vaporize.

Do you need help maintaining

and repairing an air conditioner?It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all yearJamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.Let us help you with a lot of maintenance

and installation work on your next project.To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

TAGS

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦- #HVAC #

- hvac_basics

- #hvac_fundamentals #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment