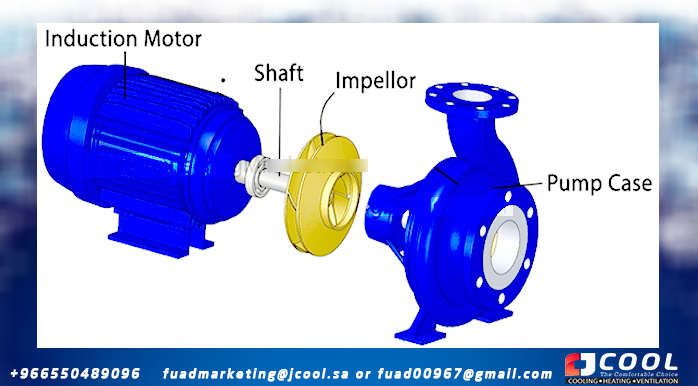

Basic concepts of centrifugal pumps. In this tutorial, we are going to look at the centrifugal type pump. The centrifugal pump is the most common type of pump used in industry, and is used in almost all commercial and industrial buildings, as well as homes, apartment buildings, even ships and some aircraft will have some form of centrifugal pump installed. .

Scroll down for YouTube tutorial on centrifugal pumps

Larger sites, especially commercial and industrial buildings, will likely have multiple pump sets. This is to service the different systems they have in the building. Typically used for heating and cooling systems, or anything that requires running water through certain pipes throughout the construction or manufacturing process.

Water first enters the pump through the inlet port. As the water enters the impeller, its rotational force pushes the water into the volute. The volutes of increasing diameter direct the flow of water towards the outlet.

The impeller has several curved vanes running from the center to the outer edge. This type of impeller is known as a reverse curve impeller, which is the most common and efficient design for moving water.

It is important to remember that these veins do not push the water like a paddle, the water actually flows between them and the veins help provide guiding force.

As the turbine begins to spin, it creates low-pressure suction at the inlets.

This low pressure suction draws the fluid into the center of the impeller.

We know that when you rotate something, it always tries to move away from the center, towards the outer edge. Imagine spinning a ball attached to a string. The ball is moving outward and is held by the string, if the string were to break, the ball would fly out.

centrifugal forces

|

| Centrifugal-force jcool |

Observe how the forces involved move the water. We have the rotating force of the wheel. When spinning objects try to move away from the center of rotation, we have an outward force. The water particles will have inertia due to the rotational force. When we combine external force with inertia, we get a resultant force at an angle. This gives us the path of the spiral trajectory that the water will take.

As the water collects in the volute it slows down and this converts its kinetic energy into static pressure. The water continues to flow behind this and this is what pushes the water, allowing it to maintain the pressure as well as its flow. This allows water to be pushed through pipes throughout the building. That is why they are used in buildings and systems around the world.

|

| Pump-volute-real jcool |

Above you can see an example of a scroll. The water flows through the center hole away from the chamber (plate is missing in picture, hole is smaller), then hits the impeller and is thrown into the volute and out the top of the casing, which is the plate attached. the right.

|

| Pump-impeller jcool |

Above you can see an example of a real pump impeller. The water flows into the central hole and into the rotating blades of the turbine.

|

| Pump-shaft jcool |

Above is a pump shaft with the induction motor rotor on the right hand side and the seal on the far left.

|

| Inside-an-induction-moto jcool |

Above you can see an example of the inside of an induction motor. The motor rotor will sit in here with the pump seal out towards the chamber.

The pumps may not be directly coupled to the motor, sometimes they are belt driven as in the example above. This is less energy efficient because the belts will slip and we will have friction losses. If you can, use direct drive, they are much more efficient and require much less maintenance.

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment