Learn how a cooling tower operates

In this topic, we will see how a cooling tower works. This will cover the basic operation of the most common type of "wet" or "open" cooling tower that you will find on most commercial and industrial high rise sites..

Why are open cooling towers the most common?

Open or wet cooling towers are the most efficient way to reject heat from the cooling system because water evaporates to remove heat. This results in the loss of water from the cooling system and is therefore not suitable for all locations and system designs.

How do they work?

Consider the cooling tower at the top of a typical office building. A centrifugal pump moves water, called “condenser water,” between the chiller in the basement and the cooling tower on the roof. The chiller adds heat to the condenser water and the cooling tower cools it by venting it to the atmosphere. Heat rejection is all the unwanted heat from the building caused by people, computers, sunlight, lighting, etc. It must also reject the heat generated by the chiller compressor.

Condenser water leaves the chiller condenser at approximately 32°C (89.6°F) and is sent by the pump to the cooling tower. Next..

parts of a cooling tower

Before seeing how a cooling tower rejects heat. Let's first look at the parts inside a cooling tower.

Fan: The fan draws in cool ambient air through filters in the base and pushes it up into the cooling tower, carrying heat and moisture with it.

Drive Belt and Drive Motor: The easiest way to get your fan blades spinning. It can also be direct drive, chain or gear.

Drift Eliminator: Causes the air to change direction and condenses some of the moisture in the outgoing air, reducing operating costs.

Condenser Water Inlet: This is where the hot water from the condenser enters the cooling tower.

Spray Nozzles: Hot water from the condenser is pushed through these nozzles, causing it to be dispersed as a spray of tiny droplets.

Fill Pack: Water spray droplets from the condenser flow downwards, increasing the heat transfer surface area and allowing air (flowing in the opposite direction) to carry away some of the heat and moisture from the evaporation.

Filter: This is where the fan draws in the air. The filter limits the amount of dirt and leaves that enter the cooling tower. Cooler, drier air enters here, then exits at the top.

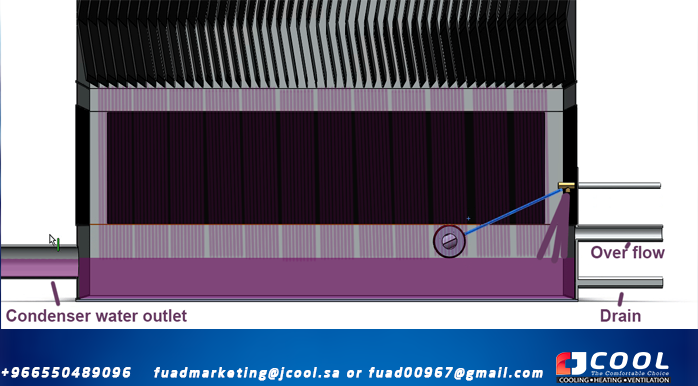

Condenser Water Outlet: This is where the condenser water will exit the cooling tower. It will come out at a lower temperature than when it entered from the top.

Make-up Water: A minimum water level is maintained in the cooling tower reservoir. Water is lost from the cooling tower through evaporation, but also when the cooling tower is emptied to remove accumulated dirt and salt.

Overflow: If the water level in the container gets too high, it will overflow this way and flow into a drain.

Drainage: Water will be drained from the cooling tower for maintenance purposes, but also periodically during normal operation when the level of impurities in the water is too high. Impurities come from the buildup of dirt and salts that build up as the water evaporates, leaving them behind. This is often known as "culling".

How does a cooling tower reject heat?

Hot water from the condenser enters near the top of the cooling tower. It passes through nozzles that spray the water in small droplets onto the fill pack. The spray increases the surface area of the water allowing it to reject more heat.

Water is sprayed into the filler pack

These droplets, coming from the spray, flow over the filling container, causing a thin film of water on its surface. The water will evaporate into the air and take the heat with it.

For increased cooling capacity, cooling towers use a fan to create more evaporation. The fan draws air through filters at the bottom of the unit and moves it up and out through the top of the cooling tower, past the fill pack and drip eliminators. The air flows in the opposite direction to that of the condenser water..

By combining the water jet, the thin film of water on the padding wrap and the flow of cold air, a great heat transfer is obtained..

Just to recap. Hot water from the condenser enters the tower and is sprayed onto the fill pack. This spray flows over the filling container creating a thin film of water on it, the water evaporates and cools. Cool, dry air enters from the bottom of the tower and passes through the fill wrap in the opposite direction of condenser water flow, which will collect heat and moisture from the thin film of water. The condenser water will leave the bottom of the cooling tower at a lower temperature. Air will blow out of the top of the cooling tower in this heat, but it will also take some of the water with it.

Water costs money. Therefore, to reduce operating costs and water consumption, cooling towers often use drift eliminators. These are located above the fill pack and spray nozzles, but below the fan..

Mist eliminators deliberately change direction to cause outgoing air to condense against the walls. This removes some of the moisture from the air which then travels back to the fill pack for further cooling and ultimately collects in the cooling tower reservoir to return to the chiller..

The cooler water from the condenser collects in the tower reservoir. This returns to the cooler where it will pick up more heat and the cycle will start again. There is usually a strainer at the outlet to ensure no foreign objects get into the pipe as this will get into the pump vanes..

A float valve in the reservoir controls the flow of water from the make-up water inlet and ensures that a minimum water level is maintained. This water is recharged by evaporative losses and also during blowdowns.

The overflow prevents too much condenser water from entering the cooling tower reservoir. The water that enters here will usually be sent to the sewer.

The drain is usually equipped with an automatic valve. Sensors in the pipes of the condenser or tank system will detect the level of impurities (dirt and salts) and will start to drain the water if the level is too high. This drain is known as a "bleed" and causes the float valve to go down, allowing fresh water to enter through the make-up inlet. The impurities are already in the condenser water and in the air, but when the water evaporates, it leaves them behind. If enough water evaporates, impurities will accumulate that can damage equipment and reduce the efficiency and effectiveness of the cooling tower, chiller, and pump.

In colder climates, some cooling tower sinks will be equipped with an electric plate warmer. It turns on at a specified minimum air temperature (eg, 41°F, 5°C) to prevent freezing.

Watch the video tutorials below to learn more..

- TAGS

- #ahu #

- blowdown

- #building_services

- #chiller

- #condenser_water

- #Cooling_Tower

- #drain

- #engineering

- #HVAC #over_flow

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #pump

- #pumps #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #

TAGS- pump system

- #centrifugal_pump

- #pump

- #pump_design

- #pumps

Comments

Post a Comment