How to read Chilled and Condenser water Schematics

Chilled water diagram and condenser water diagrams. In this article, we'll cover chilled water and capacitor schematics to learn how to read them, identify major components and symbols, and real life examples. In addition, we will cover the purpose of the main components and the different types of design. .

Scroll down for YouTube video tutorial

If you are passionate about learning all you can about engineering, and I'm pretty sure you are, you should sign up for the free online courses available on your online learning portal: Jcool Learning.

jcool Learning

Getting started is easy. Just follow this

link

|

| design variant |

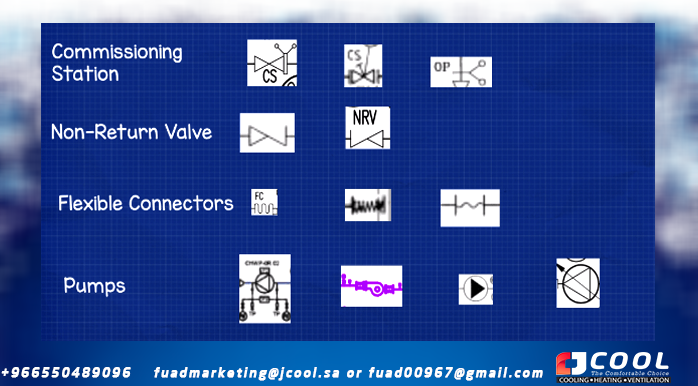

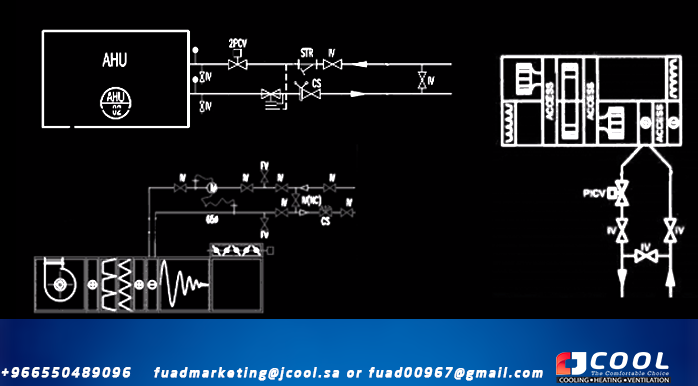

First of all, every ice water schematic you see will be completely different. The symbols used are always similar enough to recognize what they are, but always slightly different. However, they will all show how the chilled water and/or condenser system is connected and distributed around a building. They will also show the main components such as valves and pressure sensors etc. They should also indicate which floor the component is on.

In general, they do not show all the air handlers and fan coils connected to the system. Sometimes they will show the connection to the main AHUs, other times they will refer you to a separate drawing to see this detail.

If the building rents out floors to the tenants and the tenants have full control over the layout of their area, the drawing will likely only show the elevator connection to the tenant space and everything else is up to the tenant's layout. subcontractors Contractors must provide the owner with a copy of their own plans for their area.

Also, keep in mind that schematic drawings will not show all turns or the exact route through the building. They are simply a flat 2D representation of the system.

How to read the ice water diagram

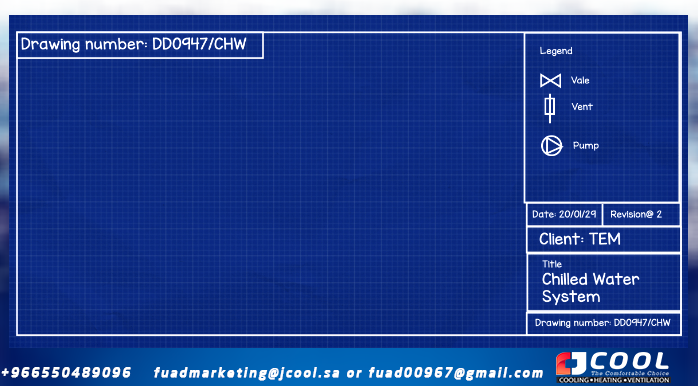

At the top left and bottom right, you'll usually find the drawing number, which is a unique identification number for that drawing.

|

| Ice Water Schematic Drawing Design |

At the bottom right you will find the title of the drawing, for example "chilled water system". You will also find the production date, revision number and other information such as the client, person and/or organization that produced the design and most importantly, on the right hand side you will find the legend listing all the symbols used. as well as its title. .

|

| Chiller, AHU, Risers, Pump Location |

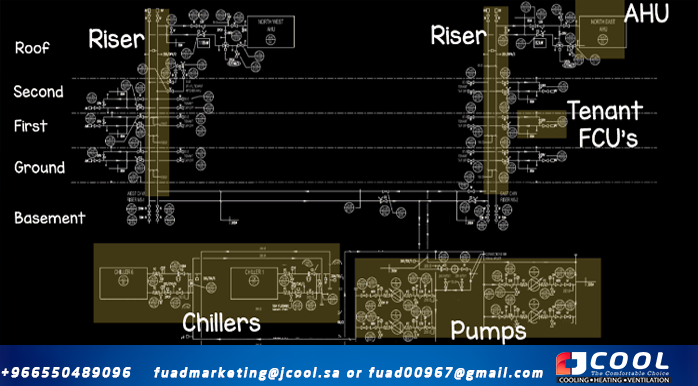

I always start by locating chillers, pumps, risers, AHUs, and cooling towers. This shows you how the system works and where each part is.

The outlines can be quite pared down and sometimes you'll need to view the information to keep up with the system.

Important Notes on Reading an Ice Water Diagram

|

| notes on reading an ice water diagram |

· You can see the direction of flow in the pipe which is indicated by arrows.

· The diameter of the pipe is sometimes indicated next to the line.

· Newer designs can show you the designed flow, velocity, pressure, and pipe diameter.

· You will also often see letters around the valves, this is just to identify what type of accessory it is. For example, an IV stands for isolation valve.

· The capital letters of "NC" mean that the valve is normally closed.

· You will also see circles with numbers and letters inside, this is the unique identifier for the connection, there should be a corresponding identification tag attached to the physical connection. You can use this number to find the correct fit, and also look up details on the record sheet, such as size and type.

· The dashed horizontal lines through the drawing mean that there is land there.

· The arrow on the pump indicates the direction of flow.

Chilled Water Diagram Examples

|

| Different representations of chillers |

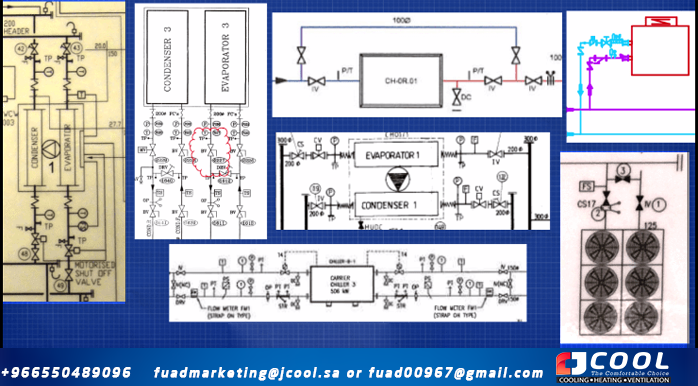

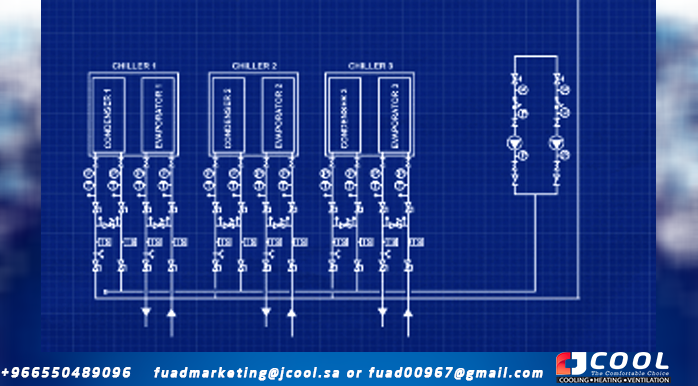

We'll start with the cooler first. I'll show you some examples of how coolers are shown on schematics because it really does vary. The two on the top right and the one on the bottom right are air-cooled chillers and the rest are water-cooled chillers. The components of each system are similar, but as you can see, design varies and not all chiller installations will use the exact same configuration or components.

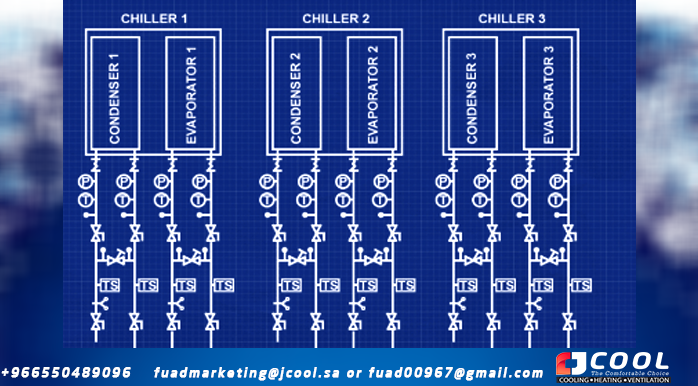

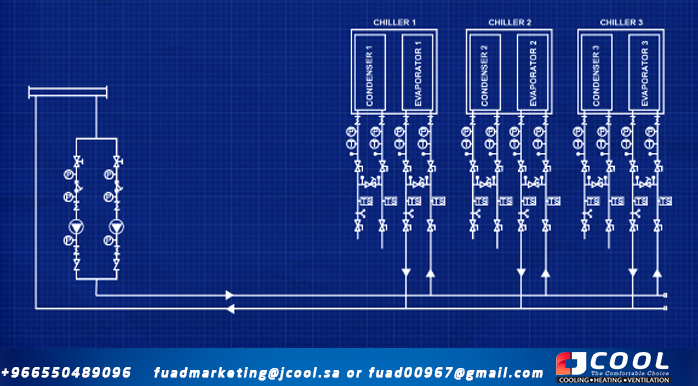

So we'll start with the chiller showing the condenser and evaporator, as well as the flow and return lines that go in and out to join the rest of the system.

|

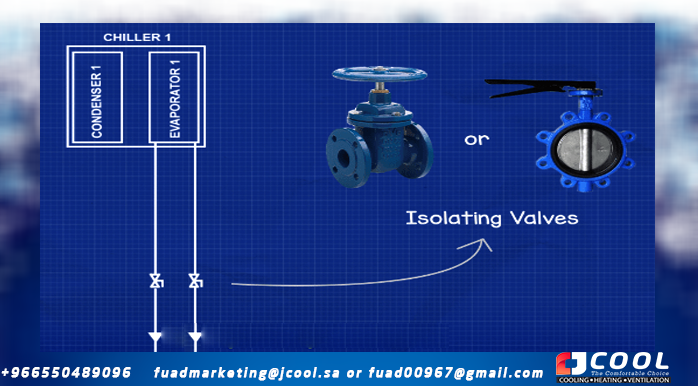

| Supply and return chiller with isolation valves |

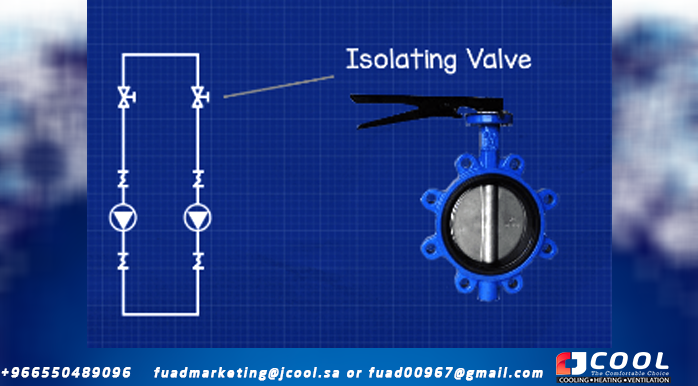

Next we will find the isolation valves which are usually butterfly valves or valves, these will be used to disconnect the chiller from the main system for maintenance. You will also find these valves on all major components such as pumps and AHUs.

|

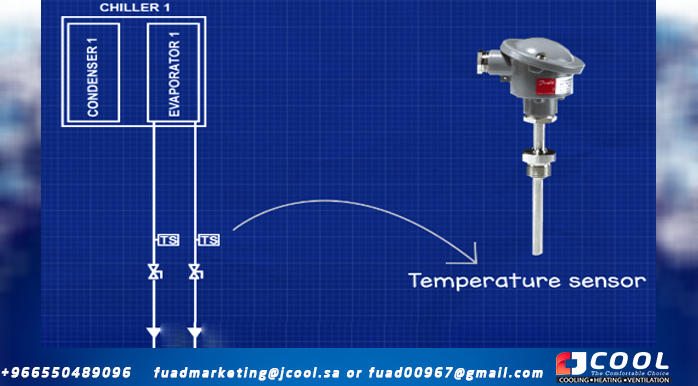

| cooler temperature sensor |

Next we will have temperature sensors to which the chiller connects. The chiller will read it to check its performance.

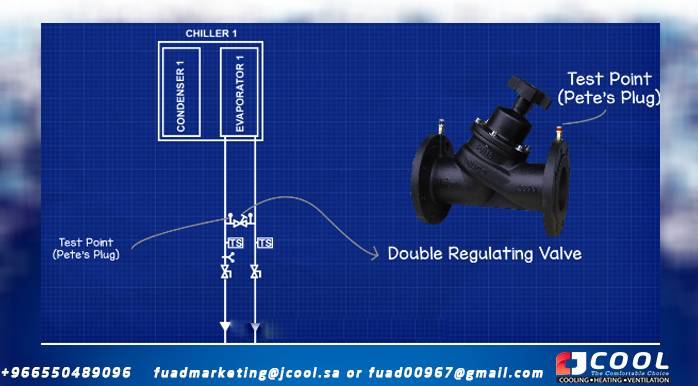

We will then have a commissioning station to measure the flow rate, this will be used to balance the system to meet design flow rates and also analyze performance. I previously made another video on how to measure the flow rate of a chiller using this device, check it out here.

|

| Chilled Water Chiller Dual Control Valve Diagram |

Then we have a bypass line and in this example there is a double check valve between the supply and return lines, but these days it is more common to have an isolation valve here that is normally closed or there is no bypass line at all. These are used to flush the system and bypass the cooler to prevent dirt from entering the heat exchanger while the system is being flushed or in this case used to balance the system as it is an old constant volume system e.g. which can be used to simulate chiller pressure drop if the chiller is isolated for maintenance.

So because we have a bypass line, we will have more isolation valves, this allows the chiller to be disconnected from the system, but the bypass line can still be used. On newer systems you will find a motorized control valve here which is connected to the building management system and allows for remote control.

|

| Pete Plug Test Point |

Then we'll have test points, also called Petes plugs, which allow technicians to plug in measuring devices, take temperature and pressure measurements.

|

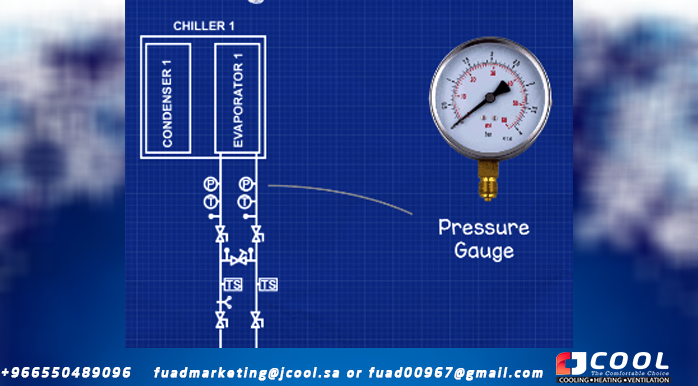

| Cooler temperature and pressure gauges |

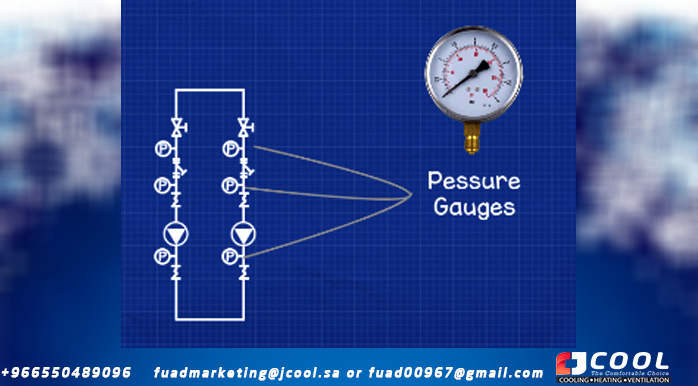

Then we will have temperature gauges to take measurements manually. Over time these usually become less reliable and the gauges often get stuck. Then we will have pressure gauges to allow manual readings. Again, these become less reliable over time and can crash.

|

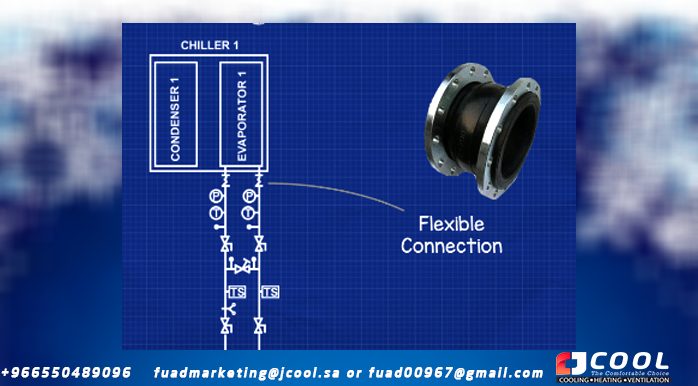

| flexible connectors |

the connection.

Usually we'll find a nearly identical setup on the condenser side, so I'll add that.

|

| Installation of several chillers. |

This layout is for a large commercial office building, so there will be multiple chillers, all with identical piping arrangements.

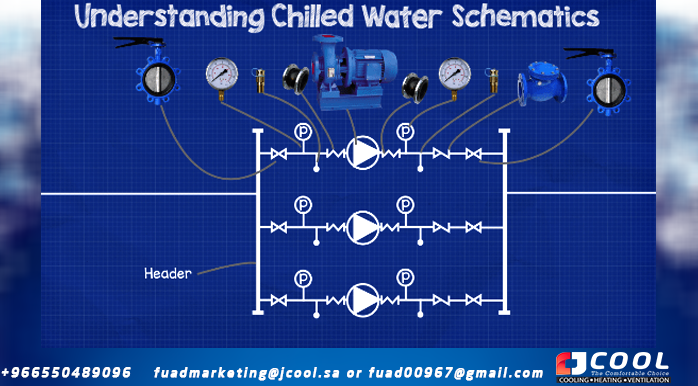

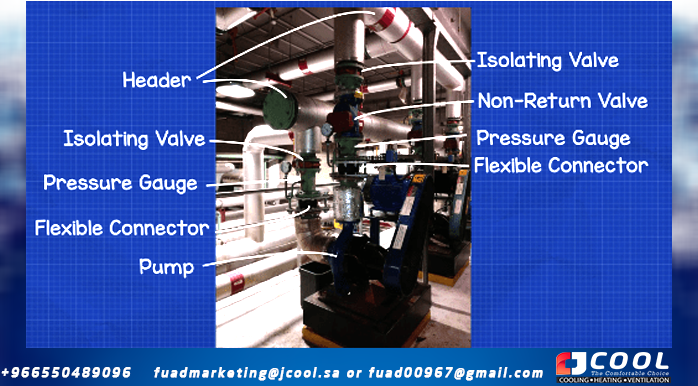

Pump sets

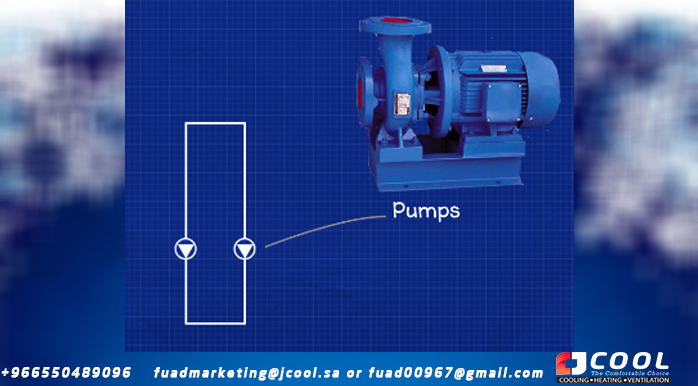

Next, we'll need pumps to push the water through the cooler and around the building.

|

| pump assembly |

To do this, we will normally have two or more pumps running in parallel, normally on duty and on standby. Again, the triangle points in the direction of the flow.

|

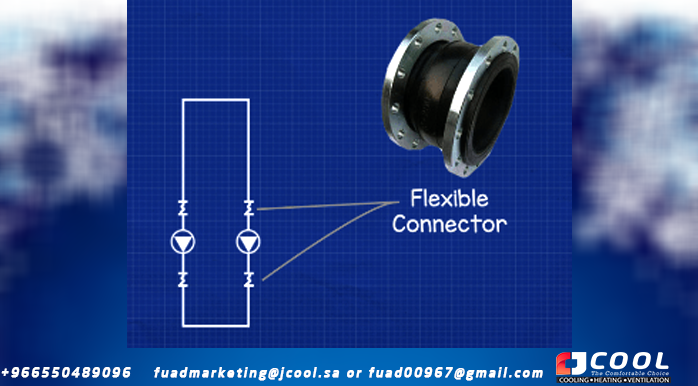

| Flexible couplings for motor pump group |

Next we will need flexible connectors because the pumps will cause vibrations.

|

| Isolation valves of the motor pump group |

Next, we'll need isolation valves so we can turn off one or all of the pumps for maintenance.

|

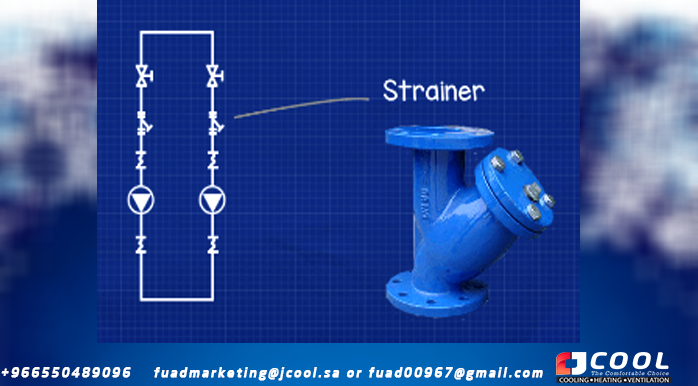

| pump filter |

Then we will have strainers that capture particles and dirt from the water and prevent them from entering the pump. Some pump configurations do not use this, some will have a large filter in another part of the system.

|

| Pump group pressure gauges |

Then we will have pressure gauges to allow manual readings

|

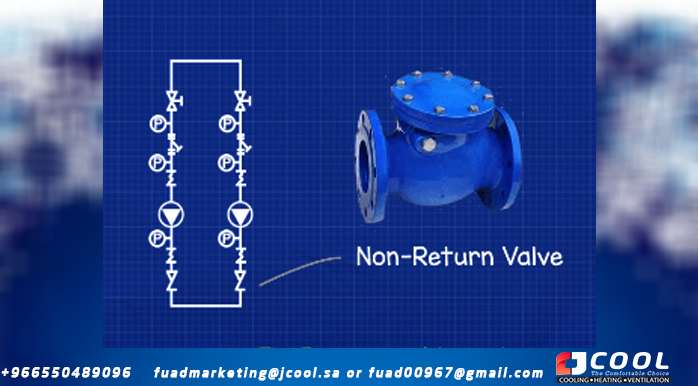

| Check Valve Pump Unit |

Next, we'll have a check valve that prevents the pressure in the pipeline from forcing the pump to spin backwards when it is turned off.

|

| Chilled Water Pump Layout Diagram |

Note that this design does not have another isolation valve after the check valve, on newer systems like this you will usually find one,

|

| Example of a pump group explained |

In the real world, the pump assembly will look like this for a centrifugal pump assembly.

We know that the pumps have to drive the water through the chiller, so we can connect the pump sets to the evaporator inlets of the chillers.

The chilled water is generated in the evaporator, so we will have to reconnect it to the pumps to create a circuit and distribute the chilled water.

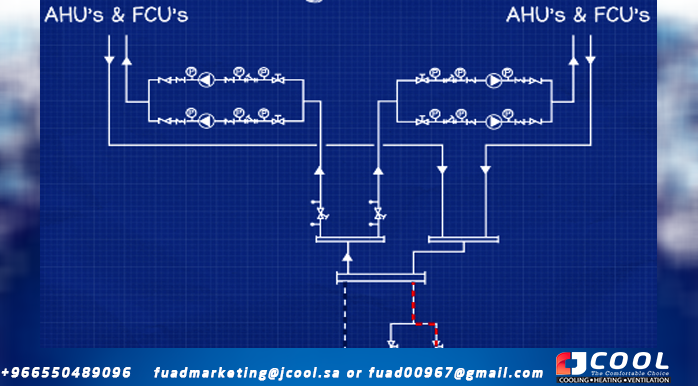

Primary and secondary systems

Note that there is a common header between the feed and return lines. This separates the system into primary and secondary loops and allows constant flow on the primary side, which is preferred by chillers as they require minimal water flow. It also allows for variable flow on the secondary side as the cooling load changes.

|

| Chilled water primary circuit |

Cold water is generated and circulated on the primary side, the secondary loops will pull the cold water out of the collector to cool the building, then reject the hot return to the collector. If the secondary side flow is low, some of the chilled water will flow to the secondary and some will recirculate to the chillers. If the flow is high in the secondary loop, all the chilled water will flow to the secondary loop and the return line will go directly back to the chillers.

Coming out of the common header is another header, this allows you to split the stream and everyone will receive an equal distribution. On the manifold outlets you may find a starting station or dual check valve, but on newer systems it will probably be in the return line.

From the collector outlets we will have other pumps to distribute the chilled water to different parts of the building, for example the east and west sides. Some designs will not have separate pumps for different parts of the building, they will simply have a set of pumps that force cold water throughout the building.

|

| Secondary circuit pumps |

These pumps will distribute water to the AHUs and FCUs, I have explained when this detail is shown or not shown earlier in the article, but I will briefly give you some examples of air handling unit connections and also some fan coil units.

|

| call to action diagram |

You will also find a pressurization unit on the chilled water side, as it is a closed system, usually connected in the return line to the main circulation pumps, as this area is not affected by the pump. This unit only maintains a certain pressure in the system.

condenser water

Now let's move on to the condenser water side. Remember that air-cooled chillers do not require a condenser system. We will need a set of pumps to push the water through the chiller and around the system so we can discharge it.

|

| Condenser water circuit |

Then connect these pumps to the condenser inlets and to another line coming out of the condenser and going to the cooling towers, located on the roof.

cooling towers

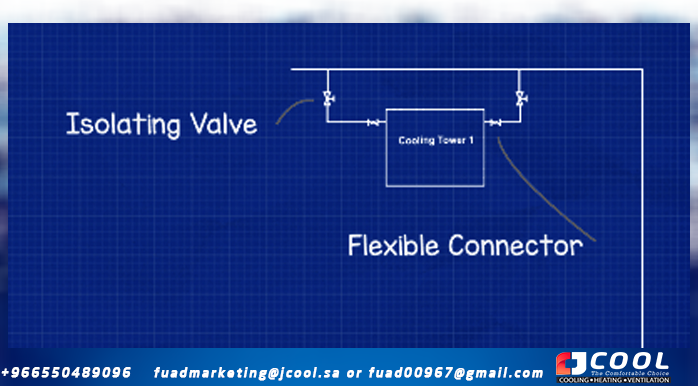

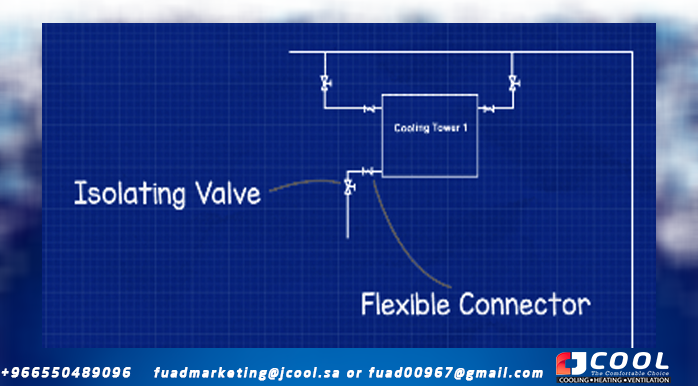

The cooling towers are connected to the riser through a manifold. These connections will require isolation valves and flexible connectors. Not all towers will have two entrances, some will only have one.

|

| Cooling Tower Connection |

At the outlet of the cooling tower we also need another isolation valve and another flexible connection. We can then reconnect it to the pumps to complete the circuit.

|

| cooling tower outlet |

Since this is a large building with multiple chillers, we will need multiple cooling towers, and in this design, we will connect them in parallel.

|

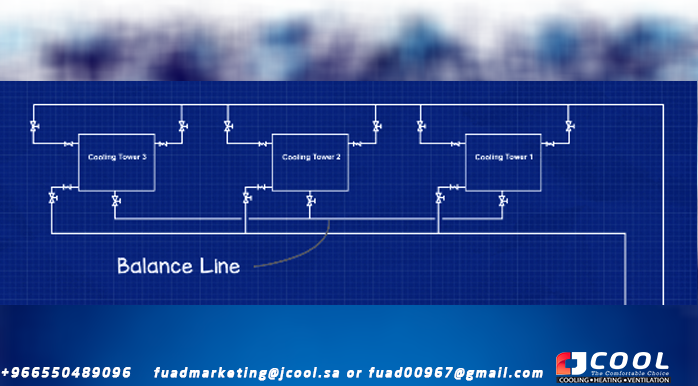

| Balancing line for various cooling towers |

Because they are in parallel with a common supply and return, we will generally find a balance line to ensure equal water levels in the reservoirs and prevent air from entering the pipes and pumps.

|

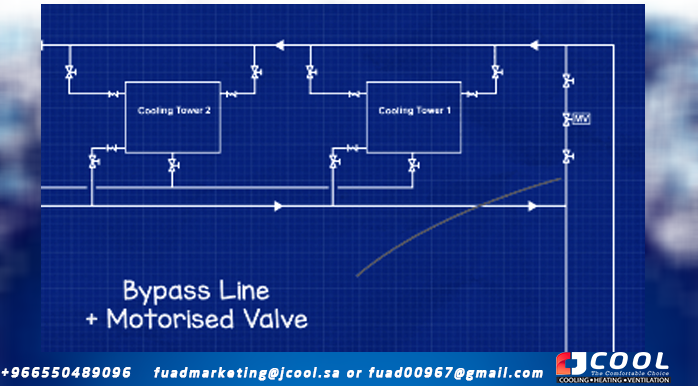

| cooling tower branch |

There may also be a bypass line with a motorized valve through the flow and return of the cooling towers. This can have various functions, such as maintaining minimum flow and also protecting the chiller against low and high pressure tripping due to condenser return water temperatures outside design limits, for example during start-up of a condenser. cold winter morning.

|

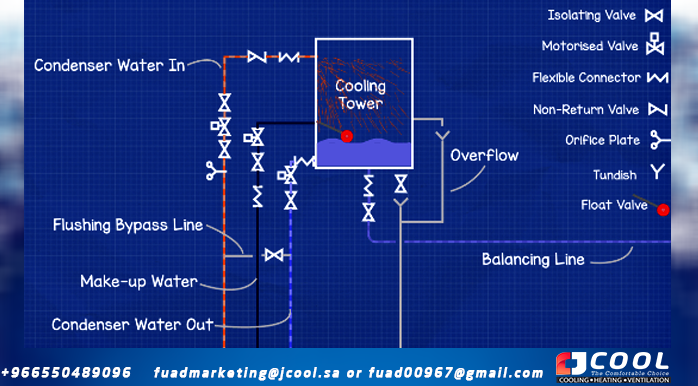

| cooling tower schematic |

Another common version of the cooling tower that you may come across will look like this. It has the supply and return lines for the condenser water. There is also a balance line between the other cooling towers, they have a compensation line that refills the water if it gets too low and there will also be an overflow and drain line. Some have a discharge line between the flow and return lines for system cleaning. If you want to know how cooling towers work, we talked about it in a previous video, click here to

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #ahu #

- air_cooled_chiller

- #air_handling_unit

- #Central_Plant

- #centrifugal_pump

- #chilled_water

- #Chilled_Water_Piping

- #Chilled_Water_Pumps

- #chilled_water_schematic

- #chilled_water_system

- #chiller

- #chiller_plant

- #chiller_plant_working_animation

- #chiller_system

- #compressor

- #condenser

- #condenser_water

- #condenser_water_schematic

- #Cooling_Tower

- #diagram

- #engineering_drawing

- #evaporator

- #fan_coil_unit

- #fcu

- #how_a_chiller_works

- #hvac_basics

- #hvac_system

- #HVAC_Training

- #non_return_valve

- #nrv

- #petes_plug

- pump #

- pump_design

- #pump_set #

- rooftop_unit

- #symbol #jcool #jamjoomCoil #Jamjoom_cooling_systems_factory

Comments

Post a Comment