Solenoid Valve Basics

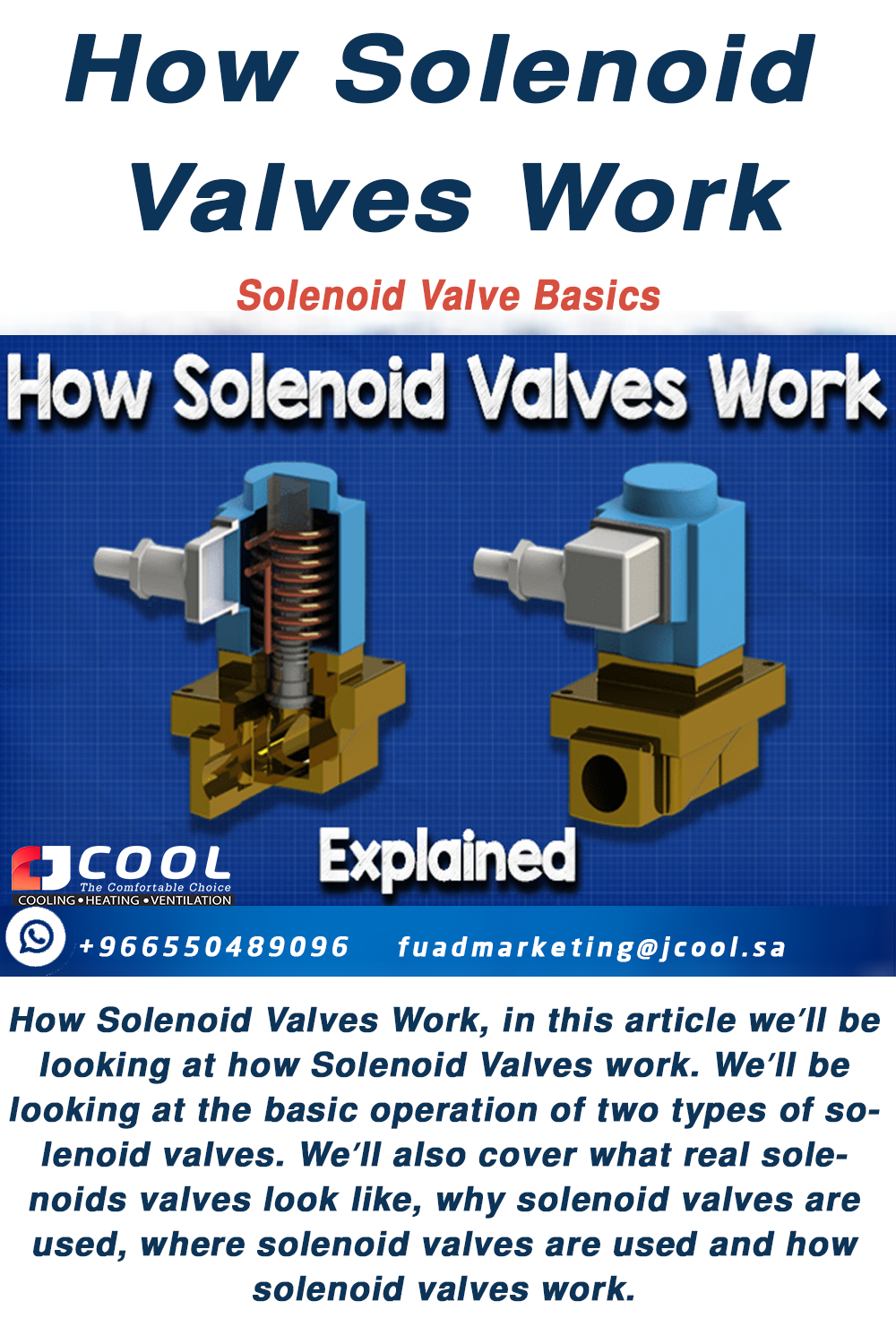

How solenoid valves work, in this article we will see how solenoid valves work. We will see the basic operation of two types of solenoid valves. We will also look at what actual solenoid valves look like, why solenoid valves are used, where solenoid valves are used, and how solenoid valves work.

Please scroll down to view the YouTube video on this item

If you work with solenoid valves, you will need to download the Danfoss Magnetic Tool app.The Magnetic Tool app, part of the Danfoss CoolApps toolkit, provides quick and easy testing of solenoid valve coils and is available worldwide for Android and iPhone.

Solenoid valves are used to convert electrical energy into mechanical energy.

Solenoid valves have a rather distinctive appearance. As expected, they have the valve body, but on top they have a block with wires sticking out. This upper part is the solenoid and the lower part is the valve, thus constituting a solenoid valve.

These valves come in a variety of shapes and sizes, I'll just show you a few examples below. The variation in shape depends on the capacity of the valve, the pressure with which it operates and the different internal mechanisms.

Why do we use solenoid valves?

Why do we use solenoid valves? These valves allow engineers to autonomously and remotely control the flow of fluids in a system. This fluid can be a liquid or a gas. For example, water, air, natural gas, oil, steam, coolant, etc. the list goes on and on.

The solenoid coil is used to operate the valve by passing an electrical current through it to create an electromagnetic field and operate the valve. This means that if it is connected to a controller, it can be controlled autonomously and remotely by a computer without the need for engineers to physically run to open and close valves. This allows systems to work much more efficiently and securely..

Where do we use solenoid valves?

Where do we use or find solenoid valves? The short answer is EVERYWHERE! Solenoid valves can be found in everything from washing machines to space rockets, although in this video we'll focus on HVAC and industrial applications.

Let's take some examples.

In commercial refrigeration systems you will almost certainly find at least one solenoid valve in the system and it is usually located in the liquid line near the expansion valve. We've also covered how regulators work before, check it out by clicking here.

Example: Air treatment unit.

This has a double direct expansion cooling coil inside to control the temperature of the air that is sent around the building. The top expansion valve and cooling coil are always on when the system is running, but the second expansion valve and cooling coil only turn on in the summer when the cooling load is too large for the system to handle alone. coil. Therefore, the solenoid valve is used here to isolate the second coil and the expansion valve until it is needed. The controller then signals the valve to open to provide additional cooling.

Example: hot gas defrost

Another very common application for solenoid valves, in refrigeration systems, is in the hot gas defrost line to control the flow of hot refrigerant to the evaporator during the defrost cycle. When moisture in the air condenses on the evaporator tubes, it freezes and causes ice buildup. We need to eliminate this to ensure efficient operation, so we open the solenoid valve to send hot refrigerant from the compressor and through the evaporator instead of the condenser. Then, once the defrost is complete, the solenoid valve closes and the system continues normally in cooling mode.

Example: beverage production

In industrial applications, we can use these valves to precisely control the flow and mixing of fluids, such as pouring the perfect amount of soft drink into a bottle on a production line.

We could also find solenoid valves used in the production line to prevent leakage. If a sensor detects a leak in the pipeline, the solenoid valve in that part of the process line automatically shuts off to prevent product waste and protect manufacturing equipment until engineers can repair it.

How do they work

There are some variations in the operation of the valve depending on the capacity required and the pressures with which it operates. We will focus on the direct drive valve, which is the simplest version.

With the direct operated valve we have the solenoid at the top which is basically a coil of wire. As you will have seen in electrical tutorial videos. When we pass an electric current through a coil, we generate an electromagnetic field. This magnetic field is what controls the valve.

We have two types of valves, normally open types and normally closed types. Let's first look at the normally closed type.

Normally Closed Solenoid Valves

Inside the valve we have the armature. The solenoid sits on top of it and completely surrounds the armature so that it is in the center of its magnetic field. Inside the armature cylinder are the piston and spring.

Operation of normally closed solenoid valves

The spring pushes the piston down in a normally closed type valve. Because the plunger is biased by the spring, it will remain in the down position to close the valve indefinitely. But, if the coil receives an electric current, it will generate an electromagnetic field and this magnetic field will pass through the piston and cause it to rise against the spring, thus opening the valve. (See YouTube video for detailed animation)

At the center of the coil, the magnetic field lines are the most compact and therefore the strongest. That's why we put the piston in the center.

Once the electric current stops, the magnetic field disappears and the spring will again force the piston to close the valve.

Normally Open Solenoid Valves

With normally open valves, we again have the coil around the armature, but this time the spring pushes the piston up so the valve is always open unless the solenoid coil is energized.

If we then pass a current through the coil, it again creates an electromagnetic field, but this time the field pushes on the piston instead of pulling on it. When the plunger is pushed, it closes the valve and stops the flow of fluid through the system.

When the electrical current is stopped, the spring pushes the piston up and opens the valve again.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #ahu

- #air_handling_unit

- #boilers

- #building_services

- #central_plate

- #chilled_beam

- #chiller

- #condenser

- #duct

- #ductwork

- #evaporator

- #fan_coil

- #fluid_mechanics #

- furnace_heater

- #heat_exchanger

- #heat_transfer

- #how_heat_exchanger_works

- #how_heat_pipe_works

- #HVAC

- #hvac_fundamentals

- #hvac_hacks

- #learn_hvac

- #plate_heat_exchanger

- #recuperator

- #refrigeration

- #roof_top_unit

- #Rotary_wheel

- #rtu

- #shell_and_tube-heat-exchanger

- #solar_thermal

- #thermodynamics

- #trench_heater #what_is_a_heat_exchanger #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #pump_system

- TAGS

- #actuator

- #automation

- #commercial_hvac

- #control

- #control_valve

- #danfoss

- el #ectrical_engineering

- #engineering

- #expansion_valve

- #heat

- #heat_pump

- #how_does_a_solenoid_valve_work

- #how_it_works

- #HVAC

- #hvac_basics

- #hvac_hacks

- #hvac_technician

- #industrial_engineering

- #maintenance

- #mechanical

- #mechanical_engineering

- #process_control

- #process_engineering

- #refrigeration

- #solenoid

- #solenoid_valve

- #solenoid_valve_working

- #technician

- #the_engineering_mindset

- #valve

- #valves

- #ventilation

- #working_principle

Comments

Post a Comment