Basic operation of how an Absorption chiller works

|

| Absorption chiller how it works |

In this article, we will look at the basic operation of how an absorption chiller works. An absorption chiller differs from other chillers because it does not have a compressor. Instead, it uses heat to generate cooling. It might sound a bit confusing, but don't worry, by the end of this video you'll understand why and how it works.

Scroll down to see the video in more detail!

If you're interested in how chillers work, we've also covered how Air cooled chillers work here

Refrigerants and chemicals used

An interesting point to note about absorption chillers is that they do not use conventional refrigerants. Instead, they use water as a coolant, which is mixed with ammonia or lithium bromide. Lithium bromide is more common because it is safer and non-toxic, so let's see how lithium bromide type water chillers work.

You can read more about how refrigerants work and

essential knowledge

Just before you go in and start looking inside an absorption chiller. I need you to understand three important concepts of this chiller and why water and lithium bromide are used.

1.

Example

· We are used to water boiling at about 100 °C (212 °F) because the atmospheric pressure around us is about 101 kPa (14.7 psi). The reason is the weight of the atmosphere on us.

· If we were to go higher in the sky, say to the top of Mount Everest, the atmosphere is thinner and water would boil at around 70 °C (158 °F) because the atmospheric pressure is around 34 kPa (4.9 psi). So you can see that as the pressure drops, the water becomes easier to boil.

· If water is placed in a vacuum chamber, it will boil at extremely low temperatures. Therefore, in the absorption chiller, the evaporator and absorption chamber are maintained under near-vacuum conditions at about 0.84 kPa (0.12 psia). This allows the water to boil at around 4.5 °C (40 °F), so very little energy is required.

By varying the pressure around the interior of the absorption chiller, water and lithium bromide can easily change phase between liquid and vapor, which is essential to provide a cooling effect.

2) The second thing to understand is that Lithium Bromide is a salt, only in liquid form. And salt attracts moisture. So if we spray lithium bromide in water vapor, the two will attract each other and mix.

|

| Lithium bromide attracts water vapor |

3) The third thing to remember is that water and lithium bromide can mix, but if you add heat they will separate. The water will rise and evaporate and the lithium bromide will sink to the bottom.

|

| Separation of water and lithium bromide by evaporation |

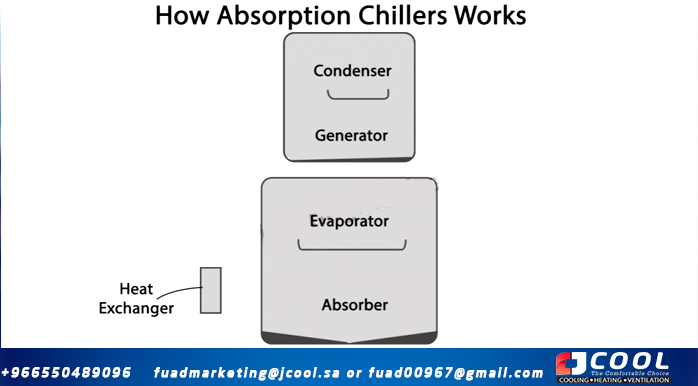

Working principle of an absorption chiller

The main components of the absorption chiller are the condenser and the generator that make up the upper chamber. The evaporator and the absorber comprise the lower chamber. There is also a heat exchanger to improve the efficiency of the system.

|

| How Absorption Chiller Works |

First, a mixture of approximately 50% lithium bromide and 40% water is pumped from the absorber through the heat exchanger and then to the generator. This line is called the line of weak solution because lithium bromide mixes with water.

The generator section is partially filled to form a reservoir for the lithium bromide and water mixture.

A heat source (hot water/steam) circulates through a pipe inside the generator tank, causing the lithium bromide and water to separate. The water will evaporate as steam and rise in the condenser section leaving the lithium bromide behind.

Lithium bromide accumulates and sinks to the bottom due to the weight of the molecules. This causes a concentration of lithium bromide liquid at the base of the generator and it will then flow down through the heat exchanger and spray onto the absorber where it can mix with the water molecules.

|

| How animation absorption chiller works |

During this time, the water vapor condenses to a liquid when it comes into contact with a cooling coil in the condenser section. Water from a cooling tower passes through a sealed pipe into the condenser to remove heat from the water vapor causing it to condense into a liquid.

This liquid water is then collected in a pan inside the condenser and flows through a pipe to the evaporator. The volumetric flow of water is regulated through a fixed orifice. The evaporator is at very low pressure, close to vacuum, which causes the water to evaporate and drop in temperature due to the rapid drop in pressure. The water reduces the temperature to about 4°C (40°F).

The "chilled water" line runs through the evaporator, just like a typical air-cooled or water-cooled chiller, and carries all unwanted building heat from the AHUs and fan coils, etc. This passes through a cooling coil where cold water from the condenser is then sprayed onto the surface to extract unwanted heat energy.

The "chilled water" will enter the evaporator coil at approximately 54°F (12°C) and when the stream of cold water from the condenser contacts the chilled water line tube, it will transfer its heat energy out of the "chilled water". chilled" and in the "condenser water" Remember that the two waters never mix, they are always separated by the wall of the pipe.

As heat is transferred through the tube wall and into the condenser water, outside the tubes, the condenser water evaporates and turns to steam due to the low chamber pressure. As it evaporates, it takes unwanted heat energy with it. Remember that we previously learned how water boils at a low temperature under low pressure. The chilled water loop has already given up its heat and by the time it leaves the evaporator it will be around 45°F (7°C) and ready to be pumped around the building to collect more heat.

Another circuit will recirculate the water that has not passed through the tubes and has not boiled. This will be pumped to the top of the evaporator and sprayed on again until it all evaporates to a vapor.

The water vapor, or steam, produced by the evaporator is then drawn and entrained into the concentrated lithium bromide solution sprayed into the absorber. It's almost like a magnetic force, the attraction is strong enough that the water particles flow on their own directly into the absorber to be together with the lithium bromide. This attraction between the water particles and the lithium bromide particles is the origin of the vacuum in the chamber. When the two fluids come into contact, they generate some heat and this, along with the heat collected by the chilled water loop, must be removed, so the cooling tower water loop also passes through the absorber. Cooling tower water also condenses residual steam particles into a liquid. The lithium bromide and water mixture collects at the bottom, ready to be pumped back into the generator to repeat the cycle.

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #absorber

- #Absorption

- #ahu

- #ammonia

- #Central_Plant

- #chilled_water

- #chiller

- #condenser

- #cooling_coil

- #cooling_effect

- #Cooling_Tower

- #evaporator

- #fan_coil_unit

- #generator

- #heat_exchanger

- #hot_water #

- lithium_bromide

- #phase_change

- #refrigerant

- #steam

- #vacuum

- #water #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment