|

| How Rooftop units work |

How roof top units or RTUs work. As the name suggests, Rooftop Units, or RTUs for short, are located on the roof of shops and small commercial buildings to provide air conditioning to defined areas.

Scroll down for YouTube video tutorial

Learn more about RTU, create your free JCOOL

learner profile by clicking

here

Join JCOOL Learning and get access to hundreds

of online courses on a wide variety of engineering topics. It's free to sign up

and you can log in at any time, which means you can learn at your own pace.

Start learning now.

Create your free JCOOL Learning

profile: http://bit.ly/LearningRooftopUnits

They

are air conditioning units and are popular because they are simple, compact,

self-contained, all-in-one HVAC units.

|

| Purpose of a roof unit |

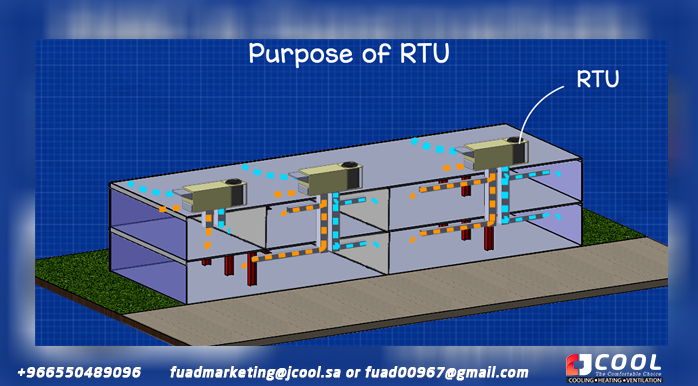

The

purpose of a rooftop unit is to distribute conditioned air to defined areas of

a building. Rooftop units are connected to ductwork that provide a defined path

for the movement of conditioned air.

|

| AHU vs. RTU |

Now, in

our latest tutorial, we take a look at Air Handling Units, or AHUs. I encourage

you to check this out and watch the video tutorial, click here to view that. If you've looked at

this, you'll notice that the units are very similar. Roof units are a type of

air handlers, the main difference is that they tend to be more compact and are

always installed on the roof, so they must be more robust and weather resistant

to face sun, rain, snow, wind, etc. Also, AHUs are often connected to a central

facility, such as chillers and boilers, to provide heating and cooling, but

RTUs are self-contained and have everything they need in one unit. That's why

they're called built-in air conditioners and we'll take a look inside some unit

models soon to find out why.

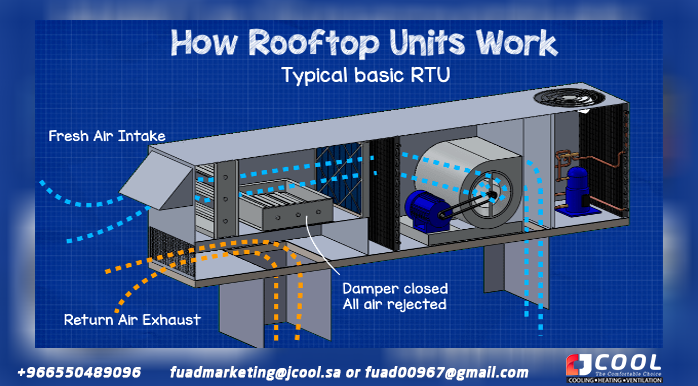

There

are many types of rooftop units and we'll look at four different typical

versions, starting with the most basic. This first unit is fresh air only, no

recirculation occurs. It draws in 100% fresh air and conditions it. Return air

is typically exhausted by an external exhaust fan to equalize air pressure.

|

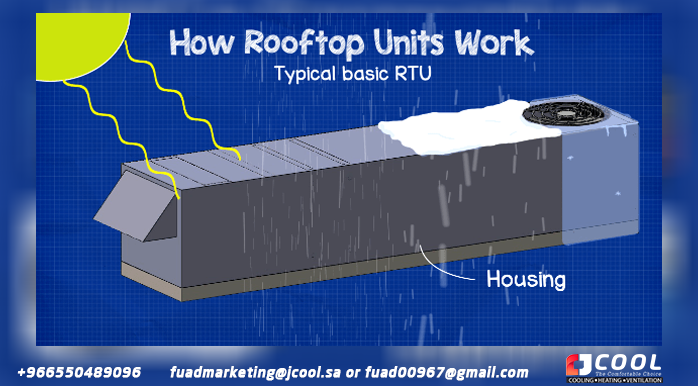

| RTU casing |

First we have the enclosure, this must protect all the mechanical and electrical equipment inside the unit from the sun, wind, rain, snow, frost, etc. There will be built-in access panels to allow engineers to access internal components and perform maintenance.

|

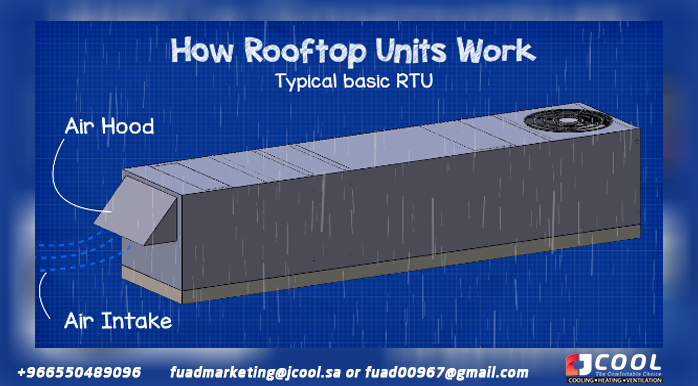

| Roof Unit Air Hood |

At one

end there is usually an air hood. This is where the outside ambient air will

enter the machine. The cover is designed this way to prevent water, snow, and

debris from entering the unit. There will usually be a screen along the inlet

of the air hood that will keep wildlife and objects out as this will cause

blockages and damage to the fan.

|

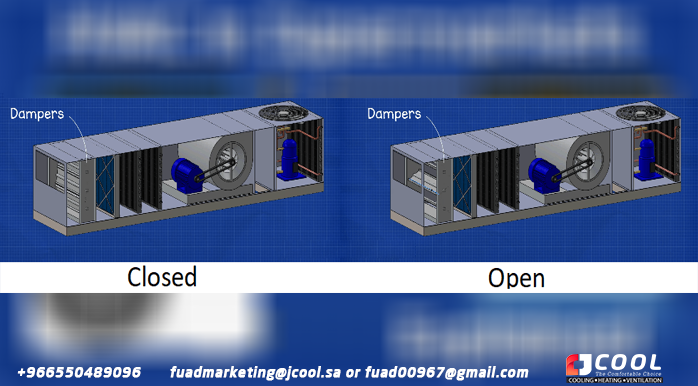

| Roof unit dampers |

The next thing we can find are shock absorbers. Not all units have them, but newer models often do. They are basically sheets of metal that rotate together. They open fully to allow air into the unit or close to seal the unit and prevent air from entering or exiting. Some can vary their open position between fully open and fully closed, this will be used to regulate the amount of air drawn into the unit from the outside, especially if recirculation is used and we'll cover that later in the video after this base model.

|

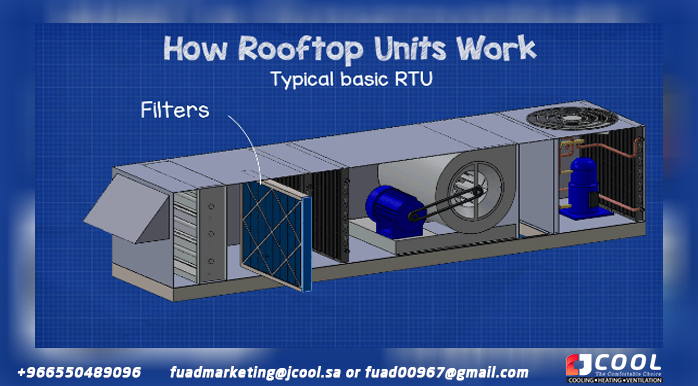

| Roof Unit Filters |

After the dampers, we will find the filters. They usually slide out of the unit from the service door. Its purpose is to purify the air by capturing dirt and dust from the fresh outside air that is brought in. If we don't have filters installed, the fan, heat exchangers, mechanical components and ducts will slowly get covered with dust and this will reduce the efficiency and effectiveness of the machine and if too much stuff accumulates it will damage the equipment. failure after a while.

|

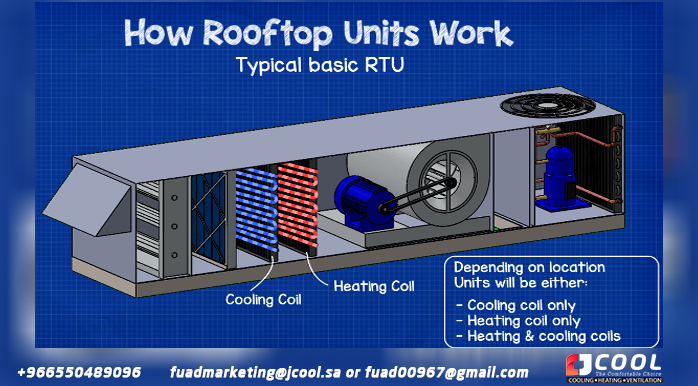

| Rooftop unit heating and cooling coils |

After the filters, we will have coils. These coils will be used to cool or heat the air by adding or removing heat energy. Depending on where in the world the RTU is located and the environmental conditions it encounters, some units will only cool, very occasionally only heat, and some will heat and cool.

If the

unit is only cooling, you will typically have a single coil connected to a

cooling unit.

If the

unit is only heating, it will be connected to a heat pump, gas burner or

electric heating element.

If the unit is heating and cooling it will

have two heat exchangers where one will be a coil that is connected to a

refrigeration unit to provide cooling and the other will probably be a tube

heat exchanger connected to a gas burner or a electric heater. For warm up.

Alternatively, one unit can provide both

heating and cooling using a single coil that is connected to a heat pump. We

covered heat pumps in a previous video, click

here to watch it.

Most units will use a refrigeration system to

provide cooling. The compressor, condenser, fan, and controls are usually

located at the rear of the unit or on the side to reject heat and away from the

intake and air conditioning inside the unit.

If you

want to learn more about the different types of heat exchangers used and how

they work, check out our other video on HVAC heat exchangers, by clicking here.

|

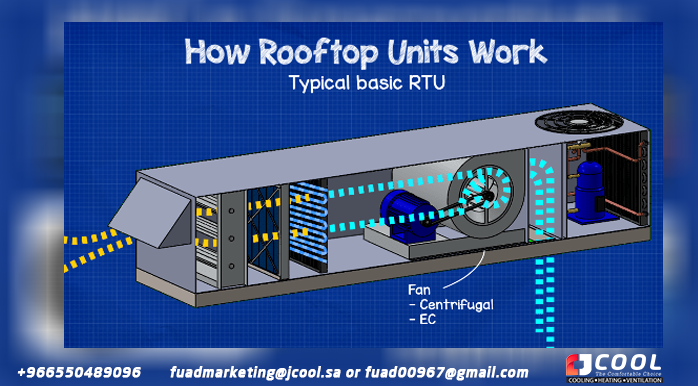

| Ceiling fan |

After the coils, we will find the fan. This is usually a belt driven centrifugal type fan, but can also be an EC type fan which is more energy efficient. The fan draws air in from outside and then through dampers, filters, and coils and then pushes it through ductwork to distribute it throughout the building.

This is

our most basic type of roof unit. So what else could we find?

|

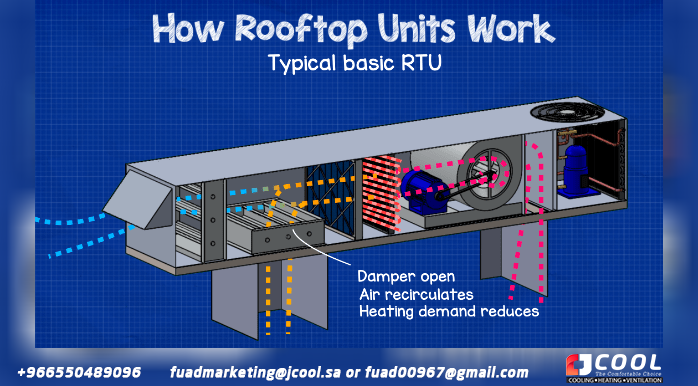

| Roof Unit Recirculation |

Some units can recirculate internal air through a return duct system. This is used to save energy, especially in winter when the outside air is very cold and the return air is warm. We can use it to reduce the heating load by mixing warm return air with cold, cold supply air.

In this

design we find a return air damper in the unit. This will work in sync with the

intake damper and both will vary their position to alter the mix of the amount

of fresh air and the amount of return air flowing through the unit. There will

always be a certain amount of fresh air coming into this type because otherwise

the building will just fill up with carbon dioxide and create an unhealthy

atmosphere. When the damper is opened, the suction of the fan draws air from

the ductwork. When the valve closes, no air is drawn in.

|

| Recirculation and discharge of the roof unit |

Another version we will come across, and this type is very common. In this design we again have the return air damper, but this time some or all of the air can be vented to atmosphere. The outside air and return air temperature, and sometimes the CO2 level of the return air, will determine how much air will be exhausted and how much will be mixed and recirculated. In these types of units, when the outdoor air temperature is lower than or close to the desired indoor temperature, 100% fresh air can be injected into the building and nothing will be recirculated, everything will be rejected when the cooling demand is satisfied. , this is called a free cooling cycle or air side economizer cycle.

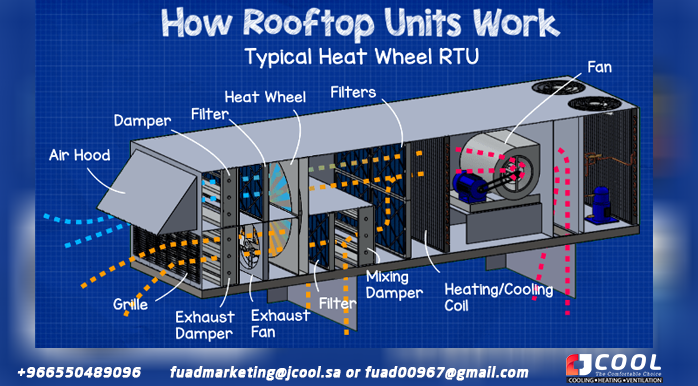

The final version we will be reviewing has a

heat wheel built right into the unit. This is gaining popularity with the

growing need for energy efficiency in buildings to reduce CO2 emissions, but

also energy and utility costs.

After that, the air will circulate through the

heat exchangers that heat or cool the air to the desired temperature.

The fan will then distribute the air

throughout the building through the ductwork to designated locations.

The return air is then returned to the RTU

through the return ductwork. Once you re-enter the RTU, you have the option to

recirculate some of the air back to the fresh air intake; otherwise everything

will go through a filter and then through the heat wheel to capture the lost

heat.

After the heat wheel we can find an exhaust

fan, otherwise the pressure caused by the main supply fan can be used to push

the air out, in some designs.

The air then passes through the exhaust damper

that serves to vary the volume of the return air mixture, as well as the

pressure inside the building, after which it passes through a grill that simply

prevents objects from entering. and wildlife from entering the unit where they

will then be expelled. from the system to the atmosphere.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment