Data Center cooling

Data center HVAC cooling systems. In this video we will look at data center hvac with a focus on the cooling systems used, how the technology works. We will compare how different strategies work and how to improve efficiency, especially with computational fluid dynamics or CFD.

Scroll down for YouTube video on Data Center HVAC

Find thousands of ready-to-use simulation models created by SimScale users that you can copy and modify for your own analysis: https://www.simscale.com/projects/

Data centers are computer server rooms that provide Internet-based networks and services. They range in size from a small single room serving a single organization and scale up to huge internet giants like Google and Facebook.

More data centers open each year as we increasingly use and rely on the Internet and remote services to store, access, and distribute our data. With this growing trend, it is important that buildings operate as efficiently as possible.

|

| Examples of data centers |

|

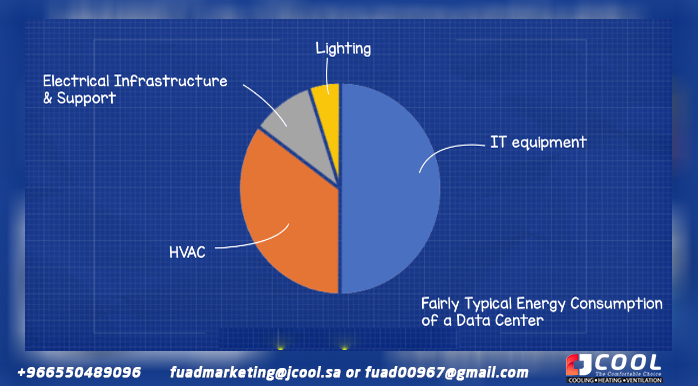

| Data Center Power Consumption Chart |

The power consumption of a typical data center can be broken down: about 50% is used by IT equipment, 35% for cooling and HVAC, 10% for electrical infrastructure and support, and about 5% for lighting. Data center electrical demand actually ranges from a few kW to megawatts, depending on size and location. So we'll look at some examples of data centers and their air conditioning systems and efficiency improvements.

|

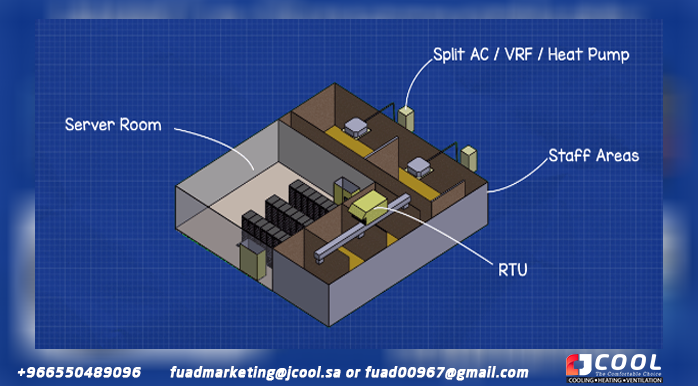

| Data Center HVAC |

The first part that we will briefly cover is about the lobby areas without data. These are the areas where the staff, security guards, engineers and technicians are normally located and these include the office, bathroom, workshop and rest areas. These areas will have an independent mechanical ventilation system and will use an air handling unit or ceiling unit to distribute conditioned air to meet human thermal comfort needs. They could also use a standalone unit or VRF system for temperature control in these areas. . I won't go into too much detail about this segment as we have covered it in our previous articles chillers, AHU

and RTU We also have videos on VRF and split AC units.

I get to the server room. One of the most common methods used today is to place server racks on a raised floor and then use computer room air conditioners or CRAC units to distribute the conditioned air to the server racks.

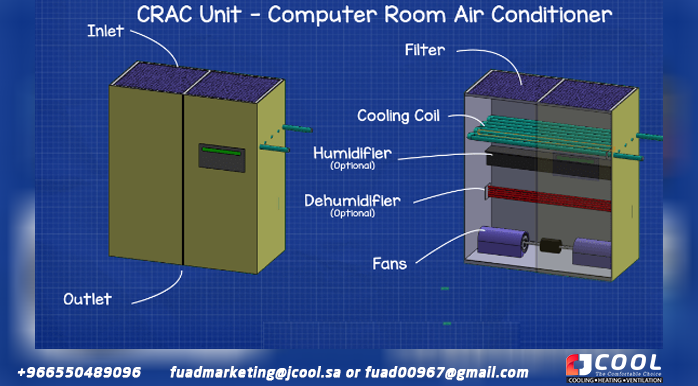

CRAC units

|

| CRAC unit of air conditioning for computer room |

CRAC units have heat exchangers into which refrigeration units or chilled water systems are connected to remove heat from server racks. Some can also humidify or dehumidify the air which is important to control static electricity in the air, have filters inside to dedust the room as well as a fan to circulate and distribute the air. For greater efficiency, CRAC units must use low consumption filters, EC or electronically controlled fans and pressure sensors in the floor vacuum to precisely control the feed rate. It is recommended to place temperature sensors in the inlet grills in the server rack to monitor the supply temperature. of CRAC units as this matches actual intake.

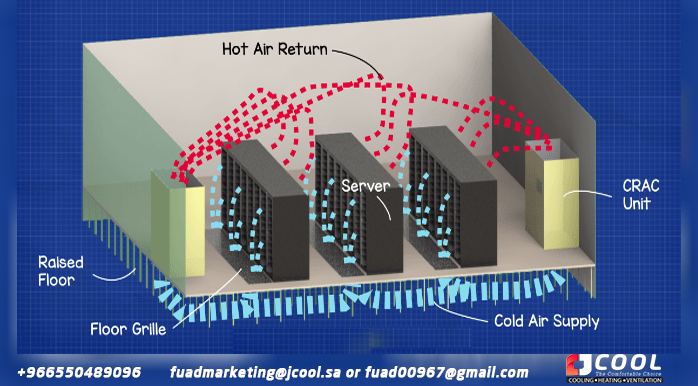

Raised floor

|

| Data Center Raised Floor |

Cool conditioned air will be forced by a fan in the CRAC unit into the void below the floor and small holes or louvers in the floor tiles will allow air to be exhausted from the void at strategic locations. This air will capture the heat and rise to the ceiling. CRAC units then draw this hot air into the unit to be reconditioned.

At first, the server racks were positioned in different ways and engineers soon realized that this was highly inefficient as cool, fresh air simply mixed with hot air escaping from the servers, meaning that the servers had different air temperatures, sometimes hot. a little cold, which leads to higher power consumption and a high failure rate of the servers.

To combat this, the servers were placed so that all server racks were oriented the same way. This was a slightly improved strategy, but very often some of the exhaust air would enter the inlet of the server racks behind it, causing the air to mix and increase in temperature.

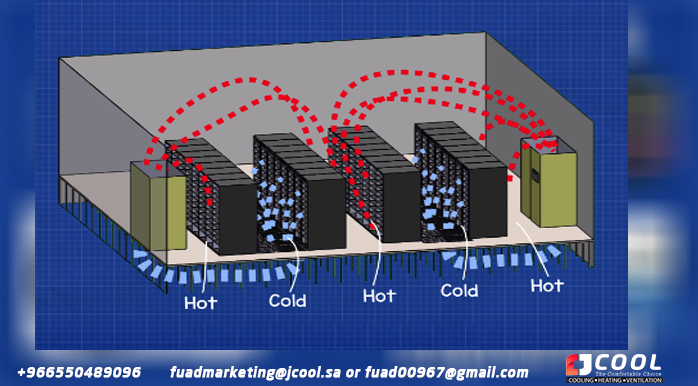

hot and cold aisles

|

| Data center hot and cold aisle |

The next strategy used, still very common today, is the use of hot and cold aisles. This is a vast improvement over previous designs as it separates the cool and cold airflow from the hot exhaust air. Cold air rises from the floor louvers and passes through the servers, all hot exhaust air is collected in the hot aisle and up to the ceiling where it is then returned to the CRAC unit. This means that the servers receive only cool, cold air and the CRAC units receive the hot exhaust air, which increases the temperature differential across the CRAC units' heat exchanger and improves the cooling efficiency of the machine.

However, this is not perfect as there will always be some mixing of the hot and cold air flows.

· Cutouts in the floor can cause air leaks, meaning cold air can seep into the warm hallway.

· Floor louvers too close to the CRAC units will cause cool air to recirculate directly into the CRAC unit and mix with the return flow.

· Gaps between servers can cause air recirculation within the server rack, this problem can be easily resolved by installing blanking plates.

· If more cold air is supplied than necessary, it will flow over the unit and mix with the discharge

· If the supplied cold air is insufficient, the hot discharge will be pulled over the top or side of the server and into the cold aisle and mix with the flow.

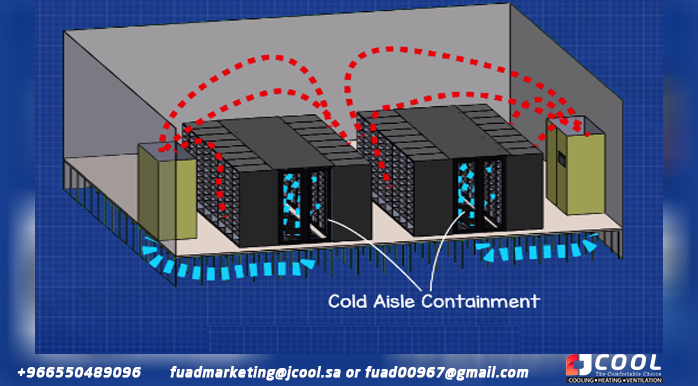

A much

improved design and one that is very popular currently for both new and

existing data centers is to use a physical barrier to separate the two air

streams. There are a couple of ways to do this, we can use a barrier around the

server rack and then contain either the hot air or the cold air.

cold air containment

|

| Data Center Cold Aisle Containment |

Cold air containment is a very popular option for existing data centers because it is easy and inexpensive to implement, which means that the return on investment is fast. Cold air fills the cold hallway, then hot exhaust fills the rest of the room with CRAC units pulling it in for reconditioning. If you have an existing data center that is not currently using this method, I recommend that you contact an installer for a quote as soon as possible.

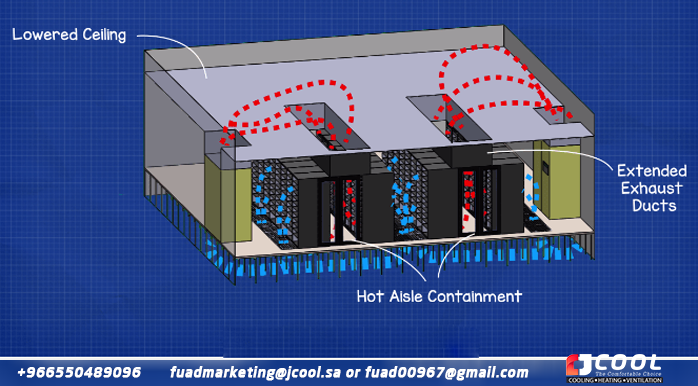

Hot aisle containment

|

| Data Center Hot Aisle Containment |

The other containment strategy used is hot aisle containment, which is more suitable for new construction because it is more expensive to install. In this strategy, cold air fills the room and the hot air that is expelled is pushed into another void within the ceiling. The CRAC unit inlet is also ducted to the ceiling to extract this hot air for reconditioning. Hot aisle containment provides superior performance and also provides a slight cooling cushion in the event of a power or cooling system failure.

CFD or computational fluid dynamics

|

| CFD Data Center - SimScale |

In fact, we can quickly and easily compare the performance of different server room configurations using CFD or Computational Fluid Dynamics. These simulations were generated using a revolutionary cloud-based CFD and FEA engineering platform from SimScale

Not only limited to data center design, it is also used for HVAC, AEC, electronic design, and thermal and structural analysis. Just a quick browse on their website and you can find thousands of templates for everything from race cars, heat exchangers, pumps and valves, all of which can be copied as a template for your own design. hey also offer free webinars,

courses and tutorials

If, like me, you have some experience creating CFD simulations, you know that this type of software is usually very expensive and requires a powerful computer to run. However, SimScale

So if you are an engineer, product designer, student or hobbyist, I recommend you try this, get your free account here goo.gl/RpAq18

|

| Cold Aisle CFD Hot Aisle Data Center |

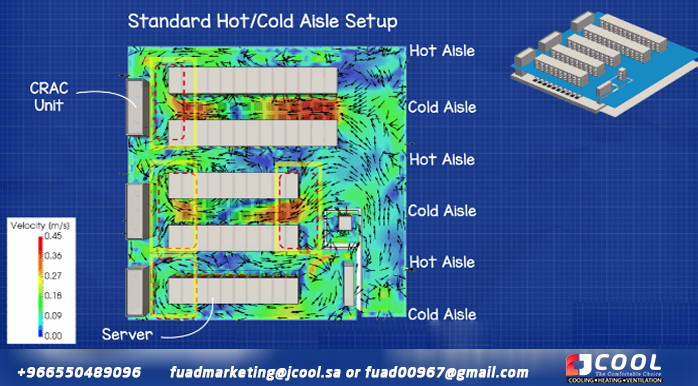

For this first design, we used a standard hot/cold aisle configuration. The arrows indicate the direction of the flow and the colors indicate the speed, you can clearly see that a lot of recirculation occurs between the lanes that I have highlighted in these charts.

|

| Hot Aisle Containment CFD Data Center |

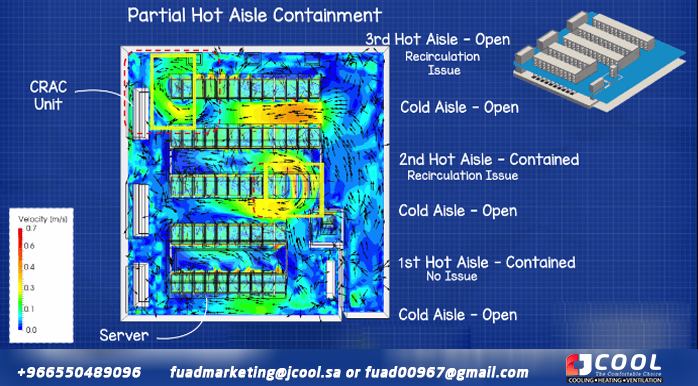

The second design uses partial hot aisle containment. You can see that the first hot aisle has a very good profile and no recirculation occurs. The second aisle, however, has some recirculation towards the end of the row, so some steps need to be installed here as blanking plates. The third hot aisle still has significant recirculation, but that's because it doesn't have a partition to separate the hot and cold airflows.

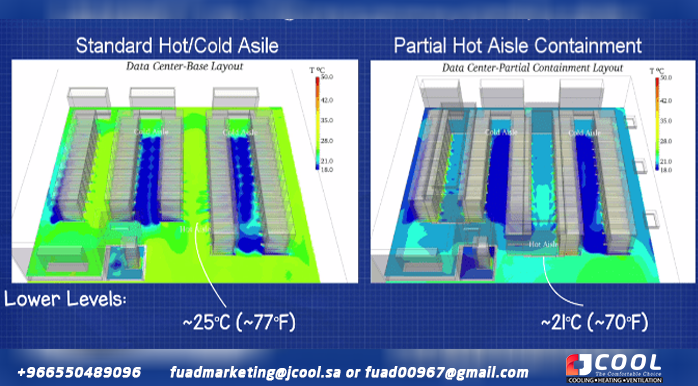

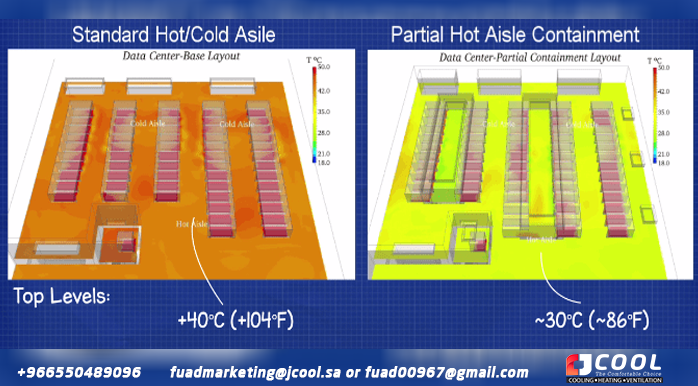

If we then run a thermal analysis of the designs, we can compare the two designs and show the resulting temperature distribution at different levels. The slice section starts at floor level and goes up to the top of the shelves.

|

| CFD Hot and Cold Aisles vs. Hot Aisle Containment |

From the comparison, we can clearly see that in the lower levels, the second design has a much colder cold aisle than the first design.

|

| Hot and Cold Aisles vs. CFD 2 Hot Aisle Containment |

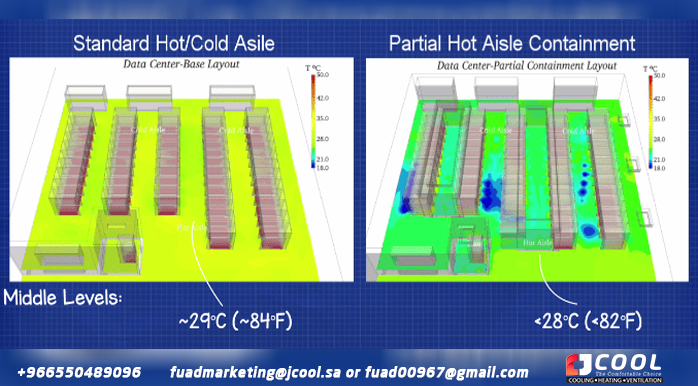

As we move to higher levels, the air temperatures begin to mix, but the second layout still maintains much cooler levels (well below 82°F/28°C), while the first layout has higher temperatures. at 29 °C or 84 °F. The ranges recommended by the standards require that the intake air temperature be between (18 and 27 °C or 64 and 80 °F) .

|

| CFD Hot and Cold Aisles vs. Hot Aisle Containment |

At the higher levels, the temperatures for the first layout are now in the higher 40+ degree range, while the second layout (partial containment) only has a maximum of 30°C or 86°F.

Therefore, the second design works much better in this case, and other design improvements can be investigated, such as hot or cold aisle full containment, using cloud-based CFD to improve system cooling, data center and optimize server power consumption. equipment and refrigeration units.

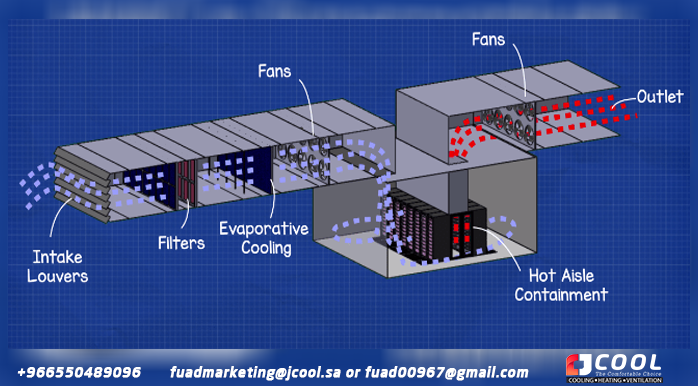

Free data center cooling

|

| Free data center cooling |

Another type of data center design that is becoming increasingly popular, can be retrofitted into some existing layouts, but is especially popular with large new purpose-built data centers like Facebook and Google, is to use free cooling. This can only be done in certain parts of the world when the environmental conditions are right, but it allows data centers to cool their servers without any cooling installation. Ambient air is drawn into the building through louvers, then heavily filtered, cooled and humidified by evaporative coolers, and then forced into the data room in a hot aisle configuration. The hot aisle exhaust is then connected to another set of fans that draw the hot air out to atmosphere.

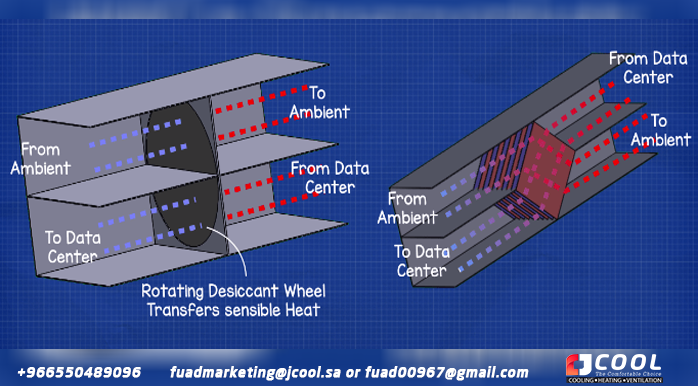

Heat exchangers

|

| Heat exchangers for data centers |

Some other cooling strategies that are slightly less common are the use of ducted systems with heat wheels or installed heat exchangers. These allow thermal energy to be transferred from one stream to another without introducing fresh air into the building. Cold air can contain dust, moisture, and salt particles that damage the server's electrical circuitry.

CRAC units

To provide cooling for CRAC units, you will typically find a chilled water system that uses a traditional chiller. Depending on the location, some systems shut down their chillers and simply use the evaporative cooling capacity of the cooling towers for normal operation, then use the chillers as a backup if the cooling towers fail to reach set point.

Some CRAC units contain their own small individual refrigeration system that uses a remote dry air cooler or discharges its heat to a condenser water system. If a condenser system is used, you will often find a free chiller attached to the system or sometimes built into the chillers, allowing for unused or minimal heat removal from the compressor using just the fans.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment