Discover the fundamentals of the CAV system, to understand its main elements and how it works.

Scroll down to see the YouTube tutorial.

What is a CAV system?

CAV stands for constant air volume. It is a type of HVAC air distribution system used in buildings where the supplied air volume remains constant but the air temperature varies.

CAV is an older design method; We still find this used in existing buildings, but it is less common in newer buildings as VAV systems are now the preferred installation option. VAV stands for Variable Air Volume. This method provides better zone control and lower power consumption.

By the way, we also covered vav systems in detail in our previous article. Check it out HERE.

Now, while constant air volume systems are becoming less common in new buildings, you can still find them installed in smaller buildings, and that's because they're easier, faster, and less expensive to install. Although the initial installation cost is lower, the cost of operating the system will potentially be much higher than a VAV system, since CAV is less energy efficient. In addition to small desks, you can still find them in places like hospital operating rooms and animal care centers to provide dedicated area control.

the VCA system

|

| VCA system jcool |

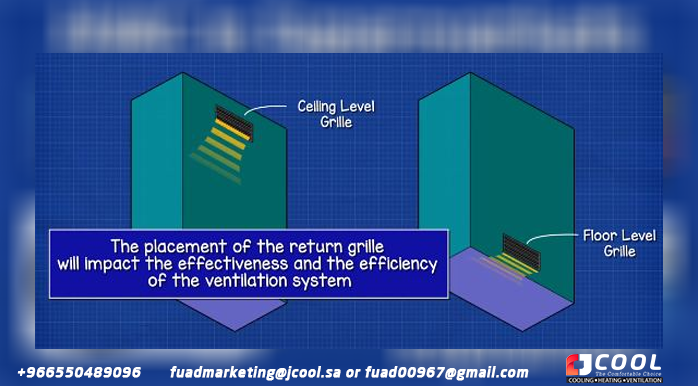

Each branch has a diffuser at the end, the diffuser has metal fins that are angled to direct the airflow and distribute it throughout the room. This air then circulates through the room and pushes the dirty used air towards the return grill. The return grill is usually on the opposite side of the room, sometimes at floor level, sometimes at ceiling level. The location of the return grill will affect the effectiveness and efficiency of the ventilation system. Industry organizations such as ASHREA, CIBSE, BSRIA provide advice on the design of such a system.

By the way, you can download a personal copy of the video HERE along with a PDF eBook, which you can store on your devices and use whenever you need HERE.

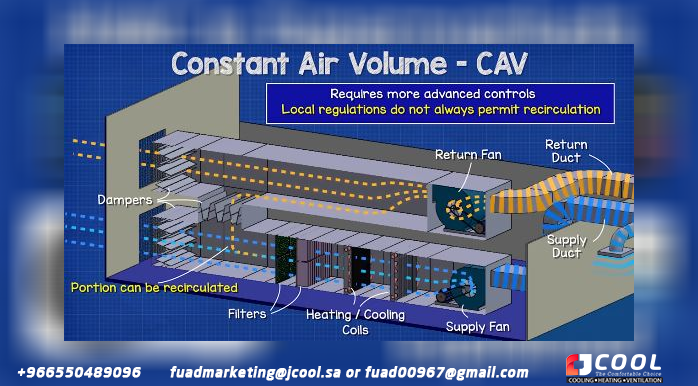

The return grill is connected to the main return duct. It again travels the length of the building and returns to the AHU. A separate return fan draws air through the grill and returns it to the AHU. This waste air can be exhausted from the building, although some AHU designs allow some of this air to be recycled back into the supply. This will reduce the power consumption of the system. This requires more advanced controls to determine when conditions are suitable for air recirculation, as some local regulations do not always allow the use of this system.

VCA system operation

Now, CAV systems have certain limitations because the supply air temperature varies, but the volume or flow rate of supplied air remains constant. Thus, while the system is running, it supplies air at a constant and constant volume and only the temperature of this air changes.

Air is typically supplied at around 13 degrees Celsius or 55 degrees Fahrenheit, but this can be adjusted based on the needs of the building. Keep in mind that heating or cooling the air consumes a lot of energy and increases the operating costs of the building.

As mentioned, the volumetric flow of the entire system and therefore of each room remains constant. We need to calculate how much air each room will receive during the design phase. It depends on the size of the room, as well as the purpose or what happens inside each room. For example, a server room will require much more cooling than a storage room. There are industry guides available that will tell you how to calculate this. Each branch is equipped with a mechanical damper that is manually adjusted at start-up to ensure correct airflow as designed.

For example, this small room in the middle may require only 3 cubic meters per second or 6,356 cubic feet per minute. While these two larger pieces on each side can require 20 to 30 cubic meters or 42,377 to 63,566 cubic feet per second. The size of the ducts, the damper and obviously the AHU fan will allow us to achieve this.

The total flow of the system depends on the size of the building. A small building may only require a total flow rate of 30 cubic meters per second or 63,566 cubic feet per minute. But it could be an old 40-story building with a huge AHU on the roof that pushes air down through the entire building, obviously it's going to be an incredible amount of moving air.

Now, one of the main problems with the CAV system is that everything connected to the AHU and the supply duct is classified as a zone. This means that all rooms connected to it receive the same air temperature regardless of their thermal load.

For example, this room here could be a very busy meeting room in the height of summer, so we have a very high demand for cooling with all the solar thermal heat gain, etc. But this room will receive the same air temperature as this small room that could be a small office for one person. This is going to be very uncomfortable for that person.

This means that the parts are not getting the required cooling demand, which means the system is very inefficient as we are generating a lot of cooling that is simply wasted because the parts don't need it.

The AHU fans would also run at 100% for the entire runtime of the system. Although you can install a variable frequency drive on the fan motor and slightly reduce airflow during low occupancy periods, be aware that this will affect the amount of cool air drawn into each room. Installing a simple VFD will not turn this system into a variable air volume system, we need a lot more controls, vav terminals, etc. It takes a lot of time and money to convert a system, but it can be done. It may not be economical to convert a system, it depends on the size of the building and the useful life of the equipment and building.

We also covered how AHU works in detail in our previous article. Check it out HERE.

From this schematic representation of the CAV system, you can see how everything is connected. Please note that all rooms are connected to this main duct here and the only form of temperature control is at the main CTA. This means that all these rooms receive air at the same temperature at a constant volume. As I mentioned earlier in the video, some AHUs have the ability to recirculate some of the air back to the steam supply, this will save energy, but we don't always find it used or perhaps building codes don't always allow it.

Getting back to the parts, the CAV design would work very well if all the parts had a similar cooling demand. Assume the building is underground or has minimal solar heat gain, and each room has a constant interior heat load that does not vary much. In this case, a VAV system would be ideal. Although it is difficult to change the design if the purpose of the room is ever changed. Sometimes we will have multiple CAV systems in a building, to give us that zone control, so each CAV system provides a different air temperature to suit the zone, otherwise each room gets the same air temperature, no matter what. what happens inside the room.

A possible solution to this is to install terminal heaters. These are usually just before the diffuser in the ceiling, and are usually electric heaters, although they can also come from your hot water system. These units will heat the incoming local air to a higher temperature, depending on the individual room. But it's obviously very energy inefficient because you're already cooling the air in the main AHU, which costs a lot of money. Then we also pay for heating the air depending on the rooms. So we waste energy and money on cooling and heating.

Typically, the air temperature for this type of system is supplied at the coolest possible temperature to satisfy the room with the highest cooling load. So, for example, this room may have the largest cooling load, so the system provides the correct air temperature for this room. These other rooms use heaters because the air is too cold.

Dual Duct CAV System

You may find dual-duct CAV systems. It's very rare to see them these days, but some older buildings still use them. With this system we have two ducts that run through and feed the cameras. One of them will carry cold air and the other will carry hot air. The air currents are then mixed by dampers depending on the individual room. The air is then collected in the main return duct and returned to the CTA to be released to atmosphere or recycled.

However, this system provides improved thermal control, compared to the standard single supply duct CAV system, but there is little humidity control. Again, not energy efficient either. Since you are supplying air through two streams, you have large duct friction losses that the fan will have to overcome. You also heat and cool the air unnecessarily.

If you have one of these systems and want to make it more energy efficient, you need to make sure that temperature reset is enabled on your system. This will monitor demand and reduce the temperature of the hot airflow to the lowest acceptable temperature, while also increasing the cold airflow to the warmest acceptable temperature. In this way, we minimize our heating and cooling energy demand and therefore our operating costs.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment