Air filtration in CTAs. In this video we are going to see the air filters in an air handling unit for HVAC systems.

Scroll down for YouTube video of air filters in AHU

|

| CTA filters |

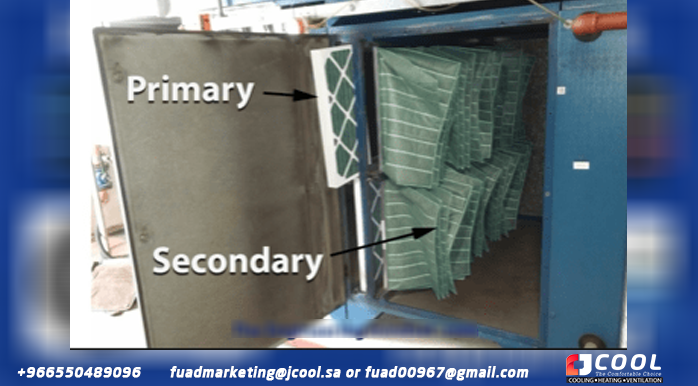

Inside an AHU we will normally find two sets of filters. The first set is known as the primary filters and we also have the secondary filters. These two elements have different functions in an air handling unit.

|

| Separate suction and extraction ducts |

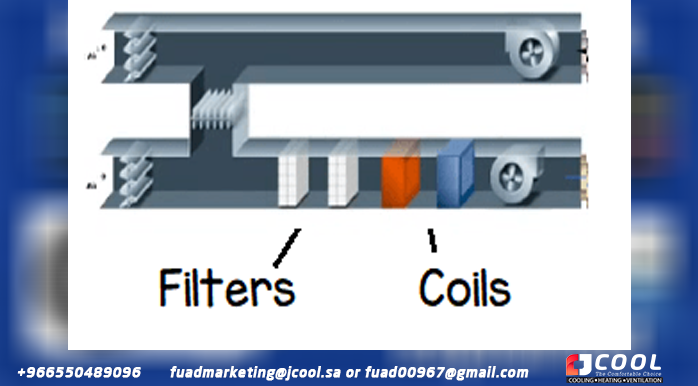

The filters are going to be one of the first things in the supply AHU, before the heating and cooling coils or the fan, and should be right after the dampers.

|

| recirculation AHU |

In the case of a recirculating air AHU system, where some of the discharge air is recirculated to the fresh air intake, filters should be downstream of the junction to filter all of the air that is recirculated and mixed with the air intake cool.

|

| Primary-filters jcool |

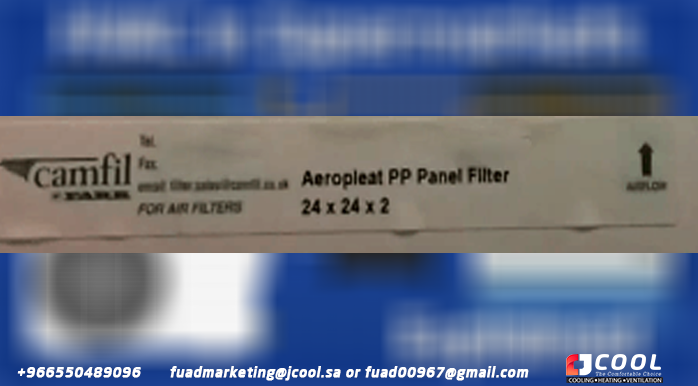

Primary filters are generally panel filters. These are there to catch the dust. They are usually made with a pleated design that increases the surface area and allows it to trap much more dust and last a bit longer than just a flat sheet. They are usually made of a synthetic material with a cardboard outer frame and are held in shape with wire mesh. Depending on the size of the AHU, you will typically need to purchase these filters in pre-made sizes that will nest to create a pervious wall that spans the direction of airflow.

These filters usually slide to the side, or some are held in place with a latch that allows them to be removed with or against the airflow.

Above is a comparison of a clean vs. a dirty primary air filter. They're pretty good at trapping dust particles down to four or five microns, but they can't really trap anything smaller than, say, one or two microns.

As you can see, the filter will be completely covered with dust. In this case, it took a few months to get to this level, but it depends on where your air intake is and where your building is. If the AHU is serving a building in a busy industrial unit with a lot of traffic and manufacturing, the air is likely to be much dirtier compared to an AHU near the ocean.

We want to get all this dust out of the air before it enters and is distributed throughout the building, because the people and equipment inside will be breathing it.

Also, we need to catch this dust before it goes deep into the AHU or ductwork, as it will stick to fans, motors, sensors, and coils. It will also accumulate inside the ducts. The more dust accumulates inside the ductwork, the harder the fans have to work to overcome this pressure drop due to the resistance it causes. If too much dust accumulates on the engine or on certain mechanical parts, it could even cause a fire.

Often primary panel filters are used to protect more expensive secondary filters from expensive filters. The cheaper primary filters are placed at the front to try to reduce the amount of dirt and dust that the more expensive ones trap and this allows them to last longer.

On the side of the primary filters you should find some details about the manufacturer, an order number, the dimension, and there should also be an arrow indicating the direction of the airflow.

Secondary filters are there to trap pollen, bacteria, and also other types of dust that were not initially captured by the primary filters. It is usually a type of bag filter made of a synthetic material.

As you can see in the image above, the secondary filters extend back a short distance in the direction of the airflow. They swell a little with the passage of air and this gives them a very large surface area. This allows the bag to capture more air at all times and the filter to last a little longer.

Above is an example of a clean and dirty secondary baghouse for an AHU. You can see that the clean version has a very soft and flexible material that has a cotton-like texture, allowing it to grab a lot of particles.

As you can see in the dirty version, this one caught a lot of dirt and pollen from the air. This would be removed and replaced. In this example, it would have taken three to six months for dirt to accumulate to this level, in this particular office building and local environment.

Since filters capture dirt, it is more difficult for air to move due to resistance to flow. This means that the fan has to overcome pressure which can consume a lot of power.

Through the filters we should find pressure sensors. Usually a digital version connected to the BMS, but also a type of physical pressure gauge that allows engineers to quickly read the pressure gauge.

There are also measurement points for pressure sensors, high side and low side. The high side reads the pressure on the front side of the bag filters. The incoming air will come into contact with the face of the filter and then flow through the filter. This will create a high pressure side upon crash. At the back we have another filter that reads the air pressure as it leaves the filter. The air has lost pressure due to the filter, so this is the low pressure side.

The two pressure readings will be different and we look at the difference to see if the filter needs to be changed. In the example above, we see that the dial shows approximately 145 pascals. In this case the manufacturer warns that around 200 – 250 pascals, the bags will have to be changed, so these filters are a little dirty but still good. You should talk to your manufacturer to find out what the pressure difference should be between your AHU filters, as they vary.

Filters vary in energy efficiency, defined by different standards. The more efficient ones will create less pressure drop, which means your fans can overcome that pressure much more easily. The fans that push air through the system will typically be between five and 10 kilowatts, so since they will be running for 12 to 24 hours per day, you may be able to save a lot of energy just by upgrading to a higher powered fan. efficient filter.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment