How they work and what's inside

How do filter driers work? In this article, we'll open up one of these filter driers to see what's inside and learn how they work. As well as discussing the purpose of each component inside.

Watch the YouTube video at the end of the article.

Do you want to know more about filter driers? Click here to register for free online filter driers courses

Dive into Danfoss Learning and continue to discover everything there is to know about filter driers and more. Create your free account to access hundreds of online courses in 26 different languages.

What is a filter drier used for?

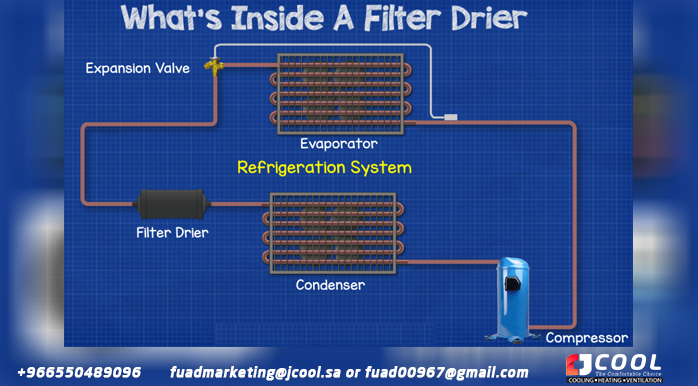

Well, they are found in refrigeration systems, and as you might guess from the name, their job is to filter and dry the coolant. They protect the refrigeration system and its components by capturing and adsorbing water particles and harmful solid substances, preventing them from circulating through the system and entering compressors, valves, sensors, etc. to keep the system running in optimum condition.

Where are the filter driers located?

This is a very typical model of filter drier and we will find them installed in the liquid line of the refrigeration system, between the condenser and the expansion valve.

We have covered the operation of expansion valves (Thermal and electronic), heat exchangers and refrigerants work in our previous tutorials, check them out.

On the side of the filter drier, you will find an arrow indicating the direction of refrigerant flow. Some heat pump models may have a bi-directional filter and the arrow points to both left and right. But in this case, we have a one-way filter drier.

On the outside we have a powder coated surface that simply prevents corrosion and the glossy black finish gives it a premium look. The case is made of steel to give it a solid structure as it will be under high internal pressure when connected to the refrigeration system.

At each end we have solder connections that can be made of pure copper or plated copper depending on the model.

So when we remove the case, we instantly see some of the key components inside. The largest component is the solid core, but we'll get to that in a moment.

Now at the inlet end of the cooler we have a big spring, the spring just pushes against the shell and the solid core, it's there just to hold the core in a fixed position inside the shell.

Then we have the nucleus or the molecular sieve. This particular model has a solid core, of which 80% is molecular sieve and 20% is activated alumina. Here I will show you some close-ups of this porous material.

The molecular structure of the solid cores acts as a filter to capture all the large dirt particles. The material is similar to a sponge in that it can also absorb and hold water. Aluminum oxide is added to capture and retain acids. Not all filter driers will have activated alumina inside, it depends on the application. Therefore, the coolant penetrates and surrounds the outside of the core and is then forced through it.

Notice this groove inside, the refrigerant will pass through this solid core and then collect in this groove to continue its flow.

At the end of the solid core we have a screen. This polyester mat traps the smallest dirt particles that might have passed through the solid core. The material is capable of capturing dirt particles down to 25 microns with minimal pressure drop.

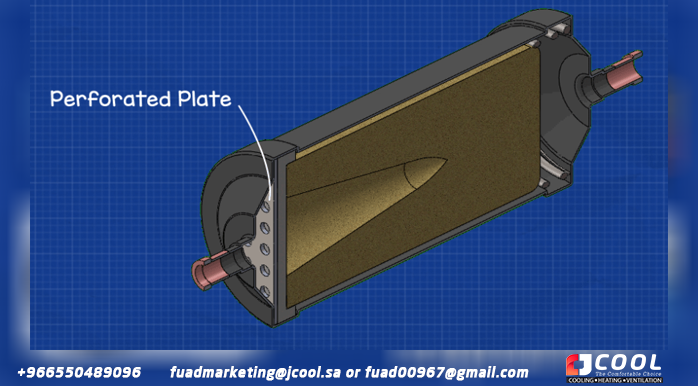

After the screen we have a perforated plate, it's just there to hold all the internal parts in position, the holes just allow the coolant to flow out.

The refrigerant then leaves the pilot filter and goes to the expansion valve.

So the coolant enters through the inlet, passes through the spring, and then surrounds the outside of the solid core. The coolant then passes through the solid core, and as it does so, dirt, moisture and acids are absorbed; then the coolant collects in the groove in the center of the core and then passes through the screen. Then it goes through the perforated plate and out of the unit after being filtered and dried, then continues to the expansion valve.

Do you need help maintaining and repairing an air conditioner?

It's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096

fuadmarketing@jamjoomarcool.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #a/c

- #air_conditioner

- #air_conditioning

- #compressor

- #condenser

- #cut_open

- #danfoss

- #engineering_mindset

- #expansion_valve

- #filter

- #filter_drier

- #how_a_filter_drier_works

- #how_it_works

- #how_to

- #HVAC

- #hvac_hacks

- #hvac_installation

- #hvac_system

- #hvac_technician

- #hvac_tools

- #HVACR #

- inside

- #inside_a_filter_drier

- #learn_hvac

- #liquid_line_filter_drier

- #maintenance #

- refrigerant

- #refrigerant_filter_drier_location

- #refrigeration

- #system_protection

- #technician

- #tev

- #txv #

- vrv

- #what's_inside

Comments

Post a Comment