MPHE for heat pumps and chillers

|

| Micro Plate Heat Exchanger |

Microplate heat exchangers. In this article, we will look at the new ultra-efficient microplate heat exchangers. We will see how they work and their purpose in refrigeration systems such as chillers and heat pumps.

Scroll down to see the video tutorial

The new jcool-design MicroPlate Heat Exchanger provides 40% more heat transfer and lower energy consumption. It is also compatible with many refrigerants, making it easy to integrate into new system designs or upgrade older equipment.

Learn more about the new jcool-Design MPHE here

Let's recap the basics of heat exchangers and their purpose. The purpose of heat exchangers, in general, is to allow the transfer of thermal energy between two fluids, without the fluids coming into direct contact with each other. The fluids can be anything, oil, water, coolant, milk, steam, etc. Although for this video we will mainly focus on microplate heat exchangers and their application in heating and cooling systems for buildings that use water and refrigerants.

|

| How heat exchangers work |

Microplate heat exchangers are plate heat exchangers that can be used for the evaporator and condenser, for example in chillers and heat pumps.

|

| evaporator-condenser plate heat exchanger |

When used for an evaporator, the vapor-liquid mixture enters the bottom of the heat exchanger, where thermal energy is transferred to the refrigerant, causing it to boil and evaporate, and then exits the top of the heat exchanger. heat with some degree of overheating.

When used as a condenser, hot refrigerant gas enters the top of the heat exchanger where it begins to transfer its thermal energy from the refrigerant to the secondary fluid that cools the refrigerant and causes it to condense into a partially subcooled liquid state.

Traditionally, shell and tube heat exchangers were used and are still used for some applications, but then came the invention of the plate heat exchanger, which is a much more compact and efficient heat exchanger. These can be in the form of welded joints or plates.

Plate heat exchangers use thin sheets of metal, called plates, to separate fluids and create separate channels for the fluids to flow and exchange their thermal energy. For this heat transfer to occur, two fluids are used, one primary and one secondary, which enter and exit through different orifices. The fluids must be at different temperatures, the greater the temperature difference, the greater the heat transfer. The two fluids will never meet or mix, they are always separated by the metal plates and thermal energy flows between them, passing through the material on the plates.

|

| Joints and brazed plate heat exchangers |

As I mentioned, there are two types of plate heat exchangers, gasketed and brazed plates.

|

| heat exchanger plate gasket |

Gasketed plate heat exchangers use a rubber gasket to separate the plates to form a gasket that directs fluids into some channels and keeps fluids out of other channels, preventing fluids from directly contacting each other. This type of heat exchanger can be disassembled for cleaning and additional plates can be added or removed to increase or decrease heat transfer capacity.

|

| Brazed Plate Heat Exchanger |

Brazed plate heat exchangers, on the other hand, also use thin plates that create channels for the passage of fluids, but they do not use gaskets, they are brazed together, usually using copper. During the welding process, all surfaces that physically touch another surface will form a weld along this connecting edge. By orienting the plates, permanent joints are created that direct the flow of fluids and prevent direct contact. Therefore, brazed plate heat exchangers cannot be taken apart for cleaning and plates cannot be added or removed, but brazed plates can always be flush cleaned and since they do not use gaskets, it is very unlikely to occur. leaks whereas gasketed plate heat exchangers have a higher chance although with proper maintenance this should not occur.

Traditionally, plate heat exchangers used slotted plates onto which V-shaped patterns of different variations were pressed.

Then came microplate heat exchangers, which are the next evolution of plate heat exchangers and the latest in heat exchanger technology. They were designed with a focus on energy efficiency and sustainability.

|

| Microplate vs. Herringbone Plate Heat Exchangers |

Instead of using traditional slotted or herringbone plates, microplate heat exchangers use small dimples. There are a number of reasons why this is a great design, firstly because the dimples distribute the fluids over the surface of the heat exchanger much more evenly, this maximizes the heat transfer surface which means there is longer for heat to transfer between fluids, dimples also cause fluids to move in a very turbulent fashion, as dimples cause fluid to change direction much more compared to typical chevron patterns.

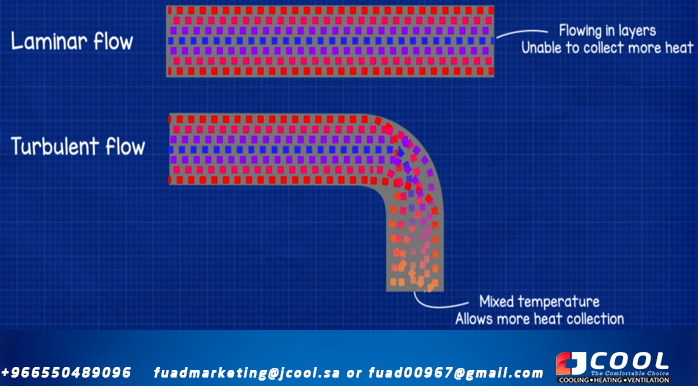

The reason turbulence is good for heat exchange is that when fluids are flowing smoothly, called laminar flow, the fluid flows in layers, with the outermost layer moving slower and the central layer moving more slowly. Quick. Then the heat is transferred only to the outermost layer. The liquid in the center can go straight through and conducts little or no heat. This means that you paid to pump fluid through the heat exchanger, but the fluid couldn't pick up much heat, so you have to pump some more to try and transfer it.

|

| laminar flow turbulent flow |

However, turbulent flow causes these layers to mix and forces heat towards the center of the flow to be entrained, allowing more heat to be transferred, thereby improving the efficiency of the heat exchanger considerably. The size, spacing, and shape of the dimples play a critical role in efficiency, so they are designed specifically for the application and required heat transfer rate and pressure drop. For example, there are heat exchangers specifically designed for heat pump evaporators and condensers, chillers, or general purpose heat exchangers such as waste heat recovery, perhaps from a data center to a district heating system. Depending on the application, you can get them anywhere from 3kW up to 400kW and up and depending on the application, they can be welded or gasketed plates.

Heat exchangers also use a counterflow design, meaning the two fluids flow in the opposite direction, to increase the rate of heat transfer and record Mean Temperature Difference (LMTD), which reduces transfer surface area. of heat required, which means that the heat exchangers can be smaller.

Like any plate heat exchanger, the purpose of microplate heat exchangers is to transfer heat from one fluid to another, not to the surrounding air or surroundings. Many people forget this and don't insulate their heat exchanger, which just wastes energy. For example, if you're using them for a cooling application, generating chilled water costs money and if you don't insulate your heat exchangers, you'll recover waste heat before it reaches its destination to supply air. conditioning. If you see a plate heat exchanger that has exposed surfaces insulate it, check with the manufacturer who should be able to provide you with an insulation panel to the exact measurements of your heat exchanger and that can be removed quickly and easily if you need to transport it. without maintenance, this will increase its effectiveness.

Also, most plate heat exchangers come with support accessories. These are there to reduce stress on the connections to prevent damage and leaks, so if your heat exchanger has them you should use them.

Some of the advantages of using microplate heat exchangers are

· Reduced refrigerant volume, heat exchangers are smaller so your system needs less refrigerant.

· The improved flow means that pressure loss is kept to a minimum, so the process requires less energy to pump water around the system.

· The heat exchanger has a higher mechanical resistance.

· Provides a stable evaporation process.

· Longer system life

· Quick and easy installation

· Smaller and lighter, fewer raw materials, less environmental impact

· Higher heat transfer rate, up to 40% higher compared to traditional herringbone design brazed plate heat exchangers.

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

Comments

Post a Comment