Guide for how and why to retrofit a HVAC system to a new environmentally friendly refrigerant

|

| Refrigerant retrofit guide |

In this refrigerant upgrade guide, we will look at how to upgrade a refrigeration system with the new green refrigerants that are coming onto the market due to changes in laws and regulations regarding the types of refrigerants that can be used.

You can watch a video about it at the end of this article.

For more information on this, I recommend visiting the Jcool website. Jcool is your source for information and resources that can help you transition the refrigeration industry to natural, climate-friendly refrigerants. They have a deep understanding of all the new regulations and their effects, and are ready to share their insights and solutions with you. They have also made useful tools such as the Refrigerant Upgrade Guide, the Low-GWP Tool and the Coolselector 2 app available for free on their website. You can access these now by visiting Refrigerants.Jcool.com.

|

| Why upgrade the coolant? |

First, the reason that laws and regulations are getting stricter on refrigerants is entirely due to the detrimental effects of older generations of refrigerants on the environment. Early generations of refrigerants were found to have punched a hole in the ozone layer, and later types of refrigerants are being phased out due to their global warming potential. We covered the basics in our previous article which you can read here or watch the video conference.

One of the disadvantages of upgrading a system with a new refrigerant is that there will be a trade off in system performance and efficiency. The system was originally designed to handle another type of refrigerant that has unique thermodynamic properties. Ideally, the entire system would be replaced to match the new coolant and provide maximum performance; however this is not always possible mainly due to financial constraints and many companies will want to maximize their initial investment. When this is the case, the only option is to update to comply with new laws and regulations.

Cooling capacity will change with the use of new refrigerant, so you need to check that the new cooling capacity will be able to meet your demands.

compatibility check

|

| cooling system |

Before upgrading a system, you'll need to evaluate the components to make sure it's compatible with a new type of refrigerant. For all items listed below, it is critical that you record the manufacturer, model, and serial number from the component nameplate. Once you have obtained this information, you should contact the provider to discuss compatibility options. If you have a handling unit, this should be an easy task; however if your system is custom built or you have a lot of spare components this can be time consuming so contact a specialist like Jcool.

When looking for nameplates on the system, you should record the normal operating conditions of the system by recording the refrigerant pressure and temperature of as many parts of the system as possible. Pay special attention to suction and discharge line, evaporator and condenser, superheat and compressor amps. You will need to use this data to calibrate your new coolant.

Compressor: The first component to check is the compressor. The compressor is the heart of the system forcing the refrigerant to move between all the major components. It's also the most expensive component and where most of the electricity will be consumed, so it's important to get it right. You will want to know the pressure and temperature limits of the compressor to ensure that it will be able to cope with the new refrigerant. Also, the oil used by the compressor may need to be changed to match the new refrigerant.

Condenser: The condenser is where all the unwanted heat will be rejected. Remember that this will have to reject all the heat from the evaporator as well as the heat produced by the compressor. You will need to verify that the condenser matches the capacity of the compressor. If the replacement refrigerant has high slip, the condenser may require an increase in area to accommodate the lower average temperature difference.

Expansion Device – If your system uses a thermostatic expansion valve, which is what most do, you may need to replace the expansion valve as it will not be compatible with the new refrigerant. The general rule of thumb is that if you compare the two refrigerant tables and there is a 3K difference in the pressure-temperature table, then you will need to replace the valve. If it's lower than this value, you may be able to adjust it if you can. You'll also want to make sure that any other valves used in the system, such as pressure control valves, will be able to cope with the new refrigerant and will likely need to be adjusted accordingly as well.

Evaporator – If the new refrigerant is a high slip type, it may result in a higher dehumidification rate because parts of the evaporator will have a lower temperature.

Valves and Seals: Unfortunately, any seals that are used around the system, such as those used on the solenoid valve, Schrader valves, and o-rings, will need to be replaced with new ones, as the current oil/coolant will have caused the seal swells and when the coolant and oil are replaced, the seal will start to leak. Also, replacement oil can react with these components and break down the material.

Lubricating Oil: The oil you are currently using in the system will also need to be replaced and it is good practice to change the oil filters as well, if your system has one. To do this, you will need to decide which retrofit refrigerant to use and find the corresponding compatible oil recommended by the supplier. It is essential to check that this oil is compatible with the compressor.

Piping: The piping will also need to be evaluated as the refrigerant being used will likely have a different density and enthalpy, which will cause different velocity and pressure drops. Of particular importance are the suction line and the oil return lines.

Controller: The controller may also need to be tuned especially for superheat as this will also change with refrigerant.

What refrigerant can your system move to?

|

| which refrigerant to adapt |

The refrigerant you need to migrate to will depend on two things.

1. what kind of system do you have

2. How long will the system be operational?

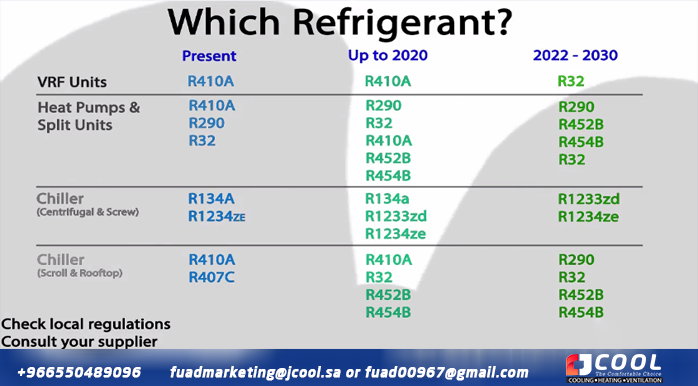

In the illustration you can see some examples of how it could be in the future. Check with your providers and specialists for more information. Also check your local laws and regulations to see how you must comply.

How to update the coolant

1. Collect the oil from the system, fill it with new oil

You will need to drain the oil from the compressor, as well as the oil separators and accumulators. Remember to record the amount of oil recovered. Talk to your refrigerant supplier as they should be able to help you get rid of this security as it probably contains small amounts of refrigerants.

2.

You will need to recover the refrigerant and record your weight. If you are not trained and competent enough to do it, do not attempt it and leave it to a trained professional. Refrigerants can be dangerous and there are large fines if you release the refrigerant into the atmosphere.

3.

Replace seals and components such as regulator and filters. Set the parameters for the new refrigerant pressure. Remember to include safety valves and control valves.

4.

Evacuate the system to remove all air, moisture, and other contaminants. Perform a leak test to ensure your system is sealed. Isolate the vacuum pump, if it does not hold its pressure, there is a leak.

5.

Recharge the system with fresh refrigerant. Talk to the refrigerant supplier as they will guide you on the size of the initial charge. Remember that if you are using mixed refrigerant, you will need to charge the system in a liquid state.

6.

Test the new system by booting it and monitoring performance. Adjust the refrigerant charge if necessary. Remember that performance will not be the same with the new coolant. Check the oil and filters as this will remove any dirt that has built up around the system. Check superheat setting.

Remember to complete the documentation and label the system with the new type of refrigerant used.

Do you need help maintaining and repairing an air conditioner?

#heatExchangers #condensers #evaporators #coolers #coils #airDucts #chiller's #jcool #Saudi_industry #cooling #ventilation #radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory #jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils #heat_exchanger #heatexchanger #coolingsystems #cooling #chiller #hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower #Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦TAGSIt's hard to keep cool when the air conditioning isn't working. Whether it's repairs, air conditioning, regular maintenance, or assistance with choosing your new unit, JCOOL professionals can keep you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL) products (condenser coil - evaporator coil - heat exchanger - air conditioning - cold evaporator - cooler - industrial air cooler - tube bundle - air heat exchanger)

Make a reservation immediately with the maintenance team before the summer heat intensifies.

Let us help you with a lot of maintenance and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

WhatsApp +966 550 489 096fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

- #Central_Plant

- #chiller

- #compressor #

- condenser

- #Controller

- #jcool

- #environmentally_friendly

- #evaporator

- #expansion_valve #

- filters

- #gaskets

- #how_to

- #HVAC #

- low_GWP #

- oil

- #Pipework

- #r134a #

- refrigerant

- #retrofit #

- retrofitting

- #split_ac #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment