Applications of different plate heat exchangers

Applications of plate heat exchangers. In this article, we will discuss the application of plate heat exchangers. Looking at the different types of joint type, brazed plate type, brazed type, and microplate type, and their applications such as chillers, heat pumps, HVAC, industrial, district power, thermal interface units, etc.

🏆 Create your free Jcool Learning profile –Click here

Join Jcool Learning and get access to hundreds of online courses on a wide variety of engineering topics. It's free to sign up and you can log in at any time, which means you can learn at your own pace. Pass the final exam and get certified in many courses.

Start learning now. Create your free Jcool learner profile –Link here

Let's first briefly recap what a heat exchanger is and how these types of plates work. A heat exchanger is a device used to transfer thermal energy from one fluid to another. The two fluids are completely separated by the heat exchanger, they never meet or mix. The fluids can be anything like water, oil, coolant, etc. Fluids must be at different temperatures to transfer heat, and heat always flows from hot to cold.

|

| Types of heat exchangers |

There are two main types of plate heat exchangers. Joint type and welded plate type. Let's first look at the type of articulation.

Gasket Plate Heat Exchanger

|

| Plate Heat Exchanger Seal |

Gasket type heat exchangers consist of multiple sheets of thin metal arranged to create channels. Gaskets are found between each of the plates and form a seal. The seal prevents fluids from mixing and leaking, but it also dictates the channels through which each fluid can flow.

Gasketed plate heat exchangers can increase or decrease their heating or cooling capacity by adding or removing internal plates. They can also be disassembled for cleaning and maintenance.

Materials used: The plates are usually stainless steel, sometimes titanium, the end plates are usually mild steel, and the gaskets are usually rubber.

Gasketed Plate Heat Exchangers Applications – You will find them in many heavy-duty HVAC applications, as well as industrial and process engineering applications, let's look at some examples of these.

Heating and cooling district:

|

| District Power Plate Heat Exchanger |

You will find these types of heat exchangers used to connect buildings to district heating and cooling networks. The district heating and cooling center distributes hot and/or cold fluids around certain central pipes to form a network. The buildings are then connected to these central networks to use the heating and cooling fluids. To connect the buildings to the networks, a plate and splice exchanger is installed between the central circuit of the buildings and the district network. The central circuit of the plant draws heat or cold from the network as needed, normally through a heat meter to measure consumption.

air conditioning-HVAC:

|

| hvac application of gasket plate heat exchanger |

You'll find gasketed plate heat exchangers used in many HVAC applications to indirectly connect chillers, boilers, and cooling towers to central plant systems. They are also used for economizer circuits and heat recovery circuits to reduce the cooling load on chillers.

Industry and manufacturing:

|

| Industrial application of the plate heat exchanger. |

Many industrial plants will use plate heat exchangers for things like pasteurization and waste heat recovery. For example, a manufacturing plant may use water to cool a newly made hot beverage. The hot finished liquid product must be cooled before bottling so that it passes through a plate heat exchanger that is connected to the refrigeration circuit of a chiller. This draws out unwanted heat without the two fluids mixing.

Advantages and disadvantages of using the seal type:

Advantages: It can be disassembled for cleaning. The heating/cooling capacity can be changed. Parts can be quickly replaced if damaged.

Cons: Leaks are rare, but more likely due to seals, higher pressure drop than shell and tube..

Welded plate and frame

|

| welded plate and frame heat exchanger |

There is one variation of the plate and frame heat exchanger that I want to cover briefly, and that is the welded plate and frame type. In this type, the plates are all welded in one piece, so they cannot be completely disassembled and the heating/cooling capacity is fixed. However, they allow the use of fluids at much higher pressures and temperatures, which is why you'll find them mostly in heavy industrial applications, power plants, and oil refineries.

Brazed Plate Heat Exchangers

|

| Brazed Plate Heat Exchanger |

Applications:They are usually used in smaller applications, but in recent years this has started to change and larger units are being produced and applied in the industry. These heat exchangers also use thin plates to separate the fluids, although the plates are brazed to make a complete seal. The brazing and alignment of the plates form the joint and dictate which channel each fluid can flow through.

Heating and cooling district:

|

| Brazed Plate Heat Exchanger Thermal Interface Unit |

Thermal interface units that connect individual apartments or houses to heating and cooling networks often use some form of soldered plate. Large brazed plate heat exchangers are sometimes used to connect buildings to district heating or cooling networks, but most currently use the union type.

heat pumps

|

| Brazed plate heat exchanger ground source heat pump |

Heat pumps often use soldered plates to connect the separate loops. This is quite common in water source heat pumps with brazed plates used for the condenser and evaporator for the refrigerant, and coils used for the water loops.

Coolers:

|

| Brazed Plate Heat Exchanger Used For Chillers |

Chillers began to be manufactured using brazed plate heat exchangers. In an air-cooled chiller, the evaporator is replaced with a brazed plate, and in water-cooled chillers, the evaporator and condenser can be replaced with a brazed plate, depending on the size of the cooling load.

heaters

|

| Water heater with brazed plate heat exchanger |

The accumulators and hot water tanks are usually indirectly connected to the heating circuits through welded plate exchangers. This separates the two and allows instant hot water to be supplied or hot water to be drawn from the storage tank on demand.

Materials:

Advantages and disadvantages of the welded plate.

Advantages: Less likely to leak. Slightly higher efficiency than joint type. More compact than joint type.

Disadvantages: Harder to clean. If it is damaged, the entire unit must be replaced.

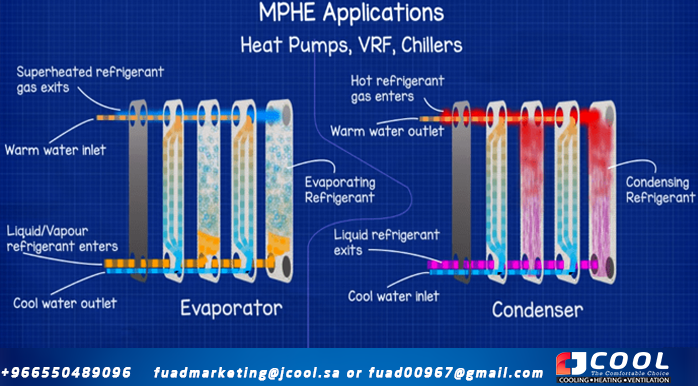

Microplate Heat Exchanger

|

| Microplate Heat Exchanger |

Micro plate heat

exchangers

Typically, the heat exchanger has a pattern like a chevron or herringbone that is pressed into the plate to increase heat transfer. Micro plate heat

exchangers

Applications

|

| Micro plate exchanger heat pump |

Heat pumps, VRF units, evaporative and condensing chillers depending on whether you have an air or water chiller.

For example, you might design or even purchase a new water-cooled chiller for a commercial building and specify that it use microplate heat exchangers or a brazed plate type instead of the typical traditional shell and tube type. This will allow for a very compact and efficient design, saving space and energy.

Advantages and disadvantages

Advantages: less weight, reduced refrigerant charge, higher heat transfer

Cons: Harder to clean though rarely needed, entire unit must be replaced if damaged, cannot increase or decrease capacity

Do you need help maintaining

and repairing an air conditioner?

It's hard to keep cool when the air conditioning

isn't working. Whether it's repairs, air conditioning,

regular maintenance, or assistance with choosing

your new unit, JCOOL professionals can keep

you comfortable all year

Jamjoom Cooling Systems Factory (JCOOL)

products (condenser coil - evaporator coil -

heat exchanger- air conditioning -

cold evaporator - cooler -industrial air cooler

- tube bundle - air heat exchanger)

Make a reservation immediately with the

maintenance teambefore the summer heat

intensifies.

Let us help you with a lot of maintenance

and installation work on your next project.

To request the service: -

Jamjoom Cooling Systems Factory

Jeddah - Second Industrial City - Street 49

fuadmarketing@jamjoomarcool.com

fuadmarketing@jcool.sa

Fuad00967@gmail.com

Eng/ Abu Hussam

#heatExchangers #condensers #evaporators

#coolers #coils #airDucts #chiller's #jcool

#Saudi_industry #cooling #ventilation

#radiators #jcool #jamjoomCoil #jamjoom_cooling_systems_factory

#jamjoom #saudiArabai #coolingtowers #cooling_tower #coolingcoils

#heat_exchanger #heatexchanger #coolingsystems #cooling #chiller

#hvac #jamjoom_hvac #jamjoom_cooling #global_cooling_tower

#Brand_Saudi_Arabia #made_in_Saudi_Arabia #🇸🇦

- TAGS

- #air_cooled_chiller

- #animated

- #bphe

- #bphx

- #brazed plate heat exchangers

- #building_services

- #calorifier

- #Central_Plant

- #chiller

- #cooling_coil

- #jcool

- #gasket

- #gasket_plate_heat_exchangers

- #heat_exchanger

- #heat_pump

- #heat_transfer

- #how_plate_heat_exxchangers_work

- #HVAC #

- hvac_hacks

- #HVAC_School

- #learn_engineering

- #learn_hvac

- #micro_plate_heat_exchanger

- #phe

- #phx

- #plate_heat_exchangers

- #refrigerant #

- thermal_energy

- #water_cooled_chiller

- #welded_plate_heat_exchanger

- #working_principle #jamjoomCoil #jamjoom_cooling_systems_factory

Comments

Post a Comment